Conveyor and Order Fulfillment Systems

Turn your warehouse into a powerhouse

The order fulfillment process refers to all the steps fulfillment centers take from the moment they receive an order until the item arrives at the shipping dock to be loaded onto a truck for delivery.

Century will engineer an efficient order fulfillment solution at every touchpoint in your operations. Our main goal is to optimize your system for output performance, reduce errors that cause returns or item breakage, and to generate profits by processing items faster with less manual interactions.

Conveyor Systems

Warehouse conveyor systems are the backbone of any automated operation, offering a continuously moving assembly line to quickly complete the processing, sortation, and distribution of a package. Conveyors typically use belts or rollers to automate the movement of cartons or pallets, powered by motors. Each warehouse has a specially engineered layout, consisting of a variety of conveyor sections, depending on function.

Benefits

- Durable and reliable, a well-maintained system can last over 20 years

- Various solutions can be added to a conveyor line to increase automation

- Conveyors offer the quickest form of transportation across a facility

- Split and full case order handling ability

Conveyor Types

There exists a number of conveyor types, each specifically designed to handle certain materials or goods, spanning across a number of industries.

If you’re looking for sortation and distribution conveyors, visit our Shipping and Sortation Systems page.

Live Roller and Gravity Conveyors

Live roller and gravity conveyors utilize cylindrical pins to propel cartons and product forward. Live roller sections are powered by a motor, while gravity conveyors are not powered by any sort of motor, but simply by gravity, like the name suggests.

These conveyors are typically used in packing lines, divert lines, extendables, or EOL operations due to their slower speed and ability to interface well with manual induction.

Belted Conveyors

A common conveyor application, belt-overs utilize belts wrapped over the slider or rollers of a conveyor bed. This allows a more stable approach to conveyance, especially for small polybags, parcels, and irregular carton sizes.

Inclines, declines, and gapping are advantages belt-overs have over live-rollers, as the belt provides conveyance stability and typically faster throughput.

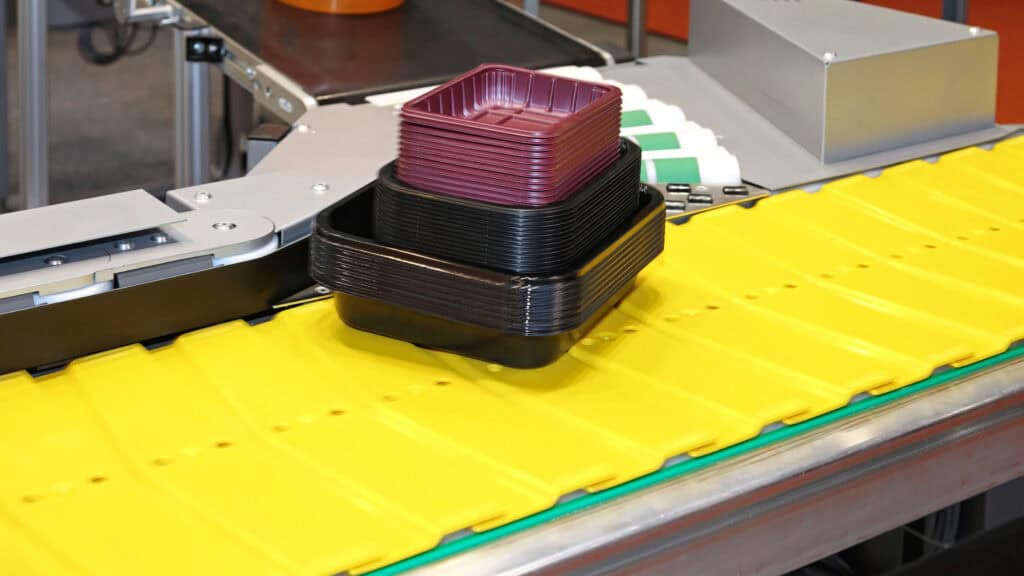

Modular Belt Conveyors

Operating in the same way as a belt-over section, modular belts differ when it comes to the material the belt is constructed of. Instead of a single vulcanized rubber belt, modular belts use individual sectors that can be removed, cleaned, or modified more easily.

Offered in a variety of formats, modular belts remove issues associated with traditional belts, like fraying, ripping, and retracking. These belts work well in food handling operations or specialized product handling lines that require additional traction, tight transfers, or ease of handling in accumulation

Conveyor Diverts

Conveyor systems utilize diverts to send product to its destination. This provides an option to sort cartons from a single line to others, without the need for a large sortation system.

Diverts come in many different shapes and sizes. Pictured is a roller-ball divert, which sends product to it’s destination via rotating balls that position the carton and convey it forward to the correct line.

Diverts also use skate-wheels, rising platforms, swinging arms, push-trays, and more to move product, and can be positioned to divert at varying angles (90-degree angles are possible).

Zero and Minimum Pressure

These accumulation conveyors are end-of-line solutions that utilize advanced sensor setups and compressors to provide gapping between items. This is to avoid products touching and causing damage and is used in situations where fragile items are conveyed.

Zero pressure indicates a line that will not let products touch each other.

Minimum pressure indicates a line that will slow products down so they lightly touch each other.

Gravity and Powered Extendable

Extendables are telescoping conveyors that can be extended or contracted in specific situations, such as loading a truck or providing a temporary line. Telescopic conveyors extend into a trailer so that packages are transported directly to the loading associate. Once loading is complete, it can be retracted.

These solutions can come in flexible gravity-powered applications, using skate wheels to move product or as a powered unit. Powered extendable conveyors use a series of telescoping belts that move based on input from the loading associate.

Conveyor Spiral

A spiral conveyor is named as such because it utilizes a gradual incline curve upwards in a spiral structure, to infeed to above-ground operations.

Spirals are compact solutions to convey products to additional levels and provide quicker processing times than stackers or employing multiple inclines.

Pallet Conveyor

Pallet conveyors focus on stable and durable movement and depending on the weight and type of pallet, different solutions are available.

These conveyor types support pallets and oversized loads. The item to be conveyed is placed on a platform that is connected to a chain. The chain is then activated and drags the platform along a conveyor section.

Much like a typical gravity conveyor, the only difference in this application is the ability to handle pallets. A pallet gravity section is typically used for staging areas, or in EOL accumulation sections.

For high-output pallet operations, live rollers are ideal to provide the flexibility to move multiple pallets, using a drag chain to operate the rollers.

These powered live roller conveyors are designed specifically for stable, slow-moving bulk items. Poly-V sections are ideal for drums, lighter pallets, and oversized bulk loads.

Robotic Order Fulfillment

Automated warehouse robots, typically defined as either an AGV (automated guided vehicle) or an AMR (autonomous mobile robot) provide transport capabilities, similar to that of a lift truck.

Benefits

- Ideal for end-of-line or goods-to-person operations

- Scalable- more systems can be implemented later on, as needed

- Flexible- systems are not “bolted down” like other automation solutions

- Can be customized for specific handling solutions

Automated Guided Vehicle (AGV)

AGVs utilize a variety of sensing components to navigate through the environment it’s deployed in. This can range from magnetic tape and QR code stickers to inductive wires and laser grids.

AGVs are ideal for transporting pallets, cartons, or non-conveyables in a static route, and can be fitted with conveyor or cart attachments for the product handled. Typically deployed in an environment in which it interfaces with a conveyor system.

Autonomous Mobile Robot (AMR)

AMRs are trackless and navigate through their environment by utilizing sophisticated sensors and programming. This allows AMRs to move totes, cartons, or carts in a highly versatile manner, since they can move freely throughout a facility.

Since AMRs can travel remotely through a distribution facility, goods-to-person operations are a favorite use case since AMRs can retrieve totes and induct them onto a packing line or directly to order fulfillment personnel.

Take the first step for true efficiency

Send Century a message to start planning your next distribution facility automation optimization project. Provide any project details in your submission, and an Automation Expert will respond promptly with next steps on your request.