Crossdocking (ˈkrȯs-däk-eng)

Crossdocking is a logistical operational method of immediately processing, distributing, and shipping received orders. This practice avoids the excess time, cost, and space related to storing inventory – while greatly increasing order throughput. Crossdocking is a method largely used in hub-and-spoke networks and among third-party and final mile distribution centers. The main operation completed at these facilities is rapid sortation to destination routes.

Key Steps in Crossdocking Operations

Receiving and Unloading

The first step in the crossdocking process is receiving goods at a designated distribution facility. Once the shipment arrives, the products are quickly unloaded from the inbound trucks or containers. The goal here is speed—unloading happens rapidly to ensure that goods spend as little time as possible in the facility.

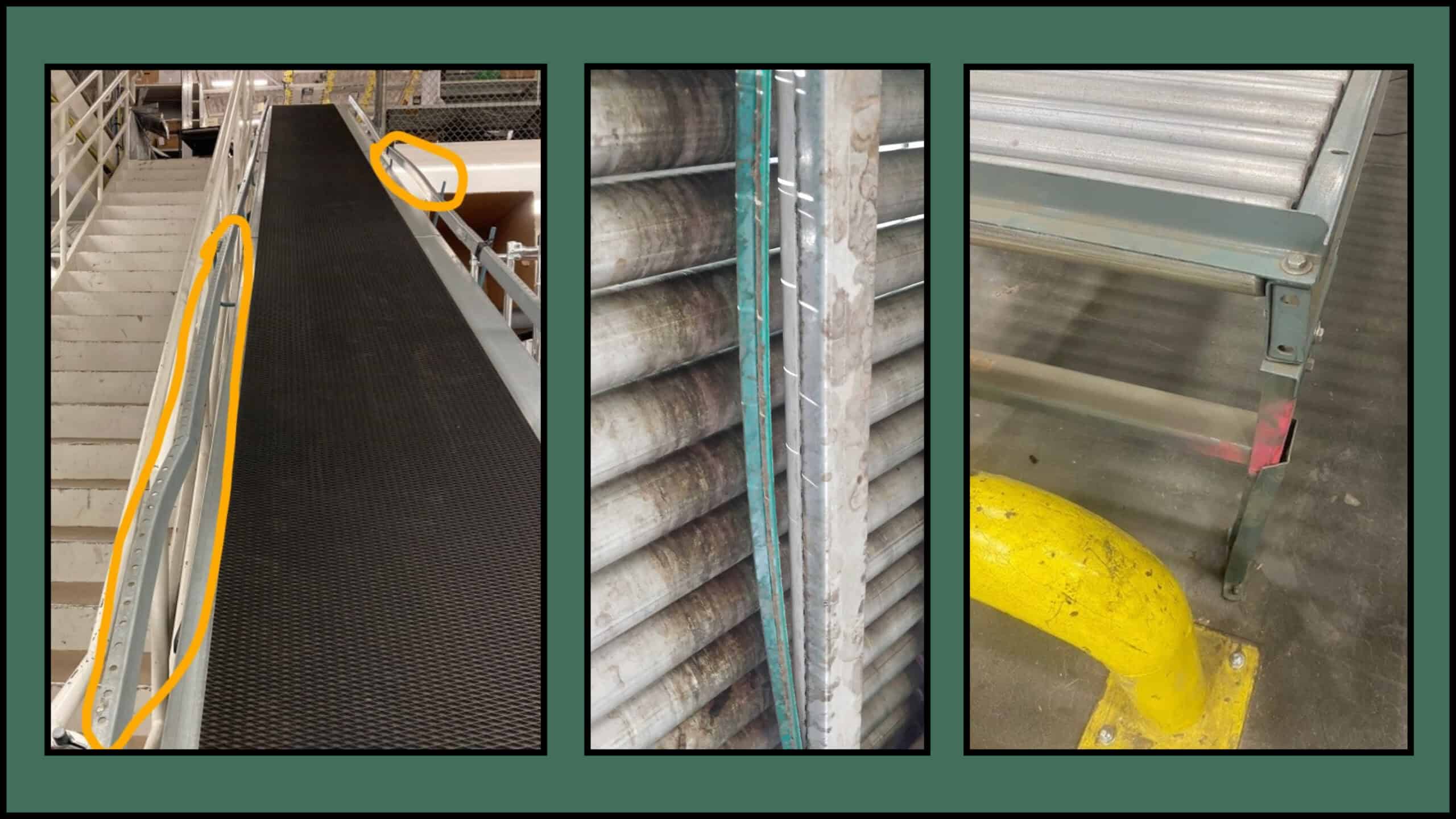

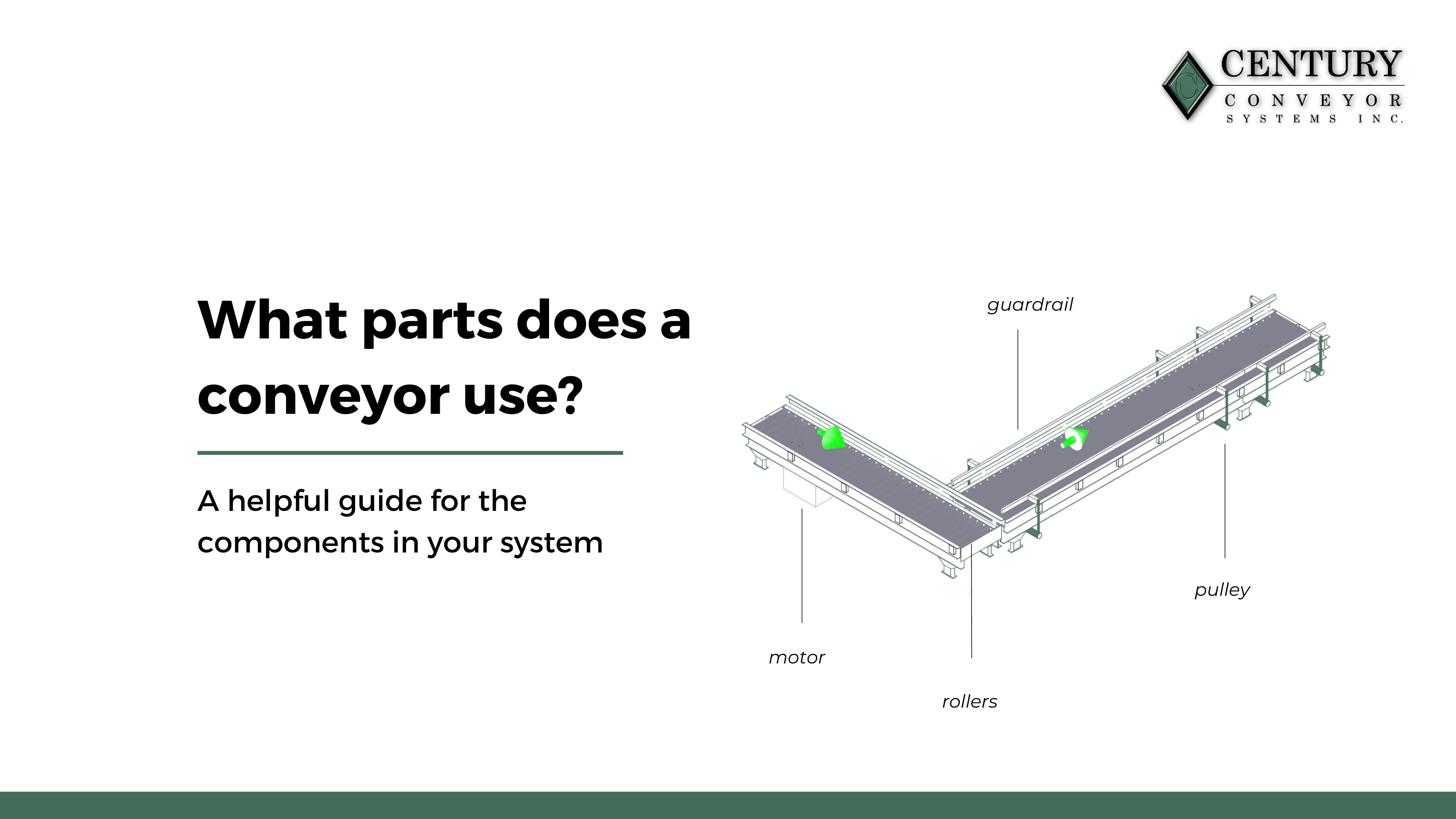

Stable and rapid automation is key at this stage so downstream operations don’t lag. If pallets are being received, forklifts can induct to a depalletizer (or a pallet conveyor line that leads to depalletization ops) to be broken down for distribution. A singulation unit using a modular belt design can be integrated to automatically position boxes into single file for operations that require packages be processed in a specific direction.

If cartons or parcels are being received, trailer extendables can be used to speed up unloading by reducing manual movement. Depending on the type of parcel, a polybag for example, may need to unload only from certain docks – as those lines may lead to a sorter that can handle the package type. It is not uncommon for a crossdock system to have more than one type of sorter.

Product Handling

After unloading, products are immediately moved to their next destination. This step is crucial, as it ensures that products flow seamlessly through the system. Depending on the type of product and the final destination, goods may either be prepared for outbound shipping or temporarily held in a staging area.

In a crossdocking setup, good-to-person and storage operations are typically not present, as product comes in – sorted – and goes right out. Integrators design crossdock systems to minimize manual labor touchpoints, but since the name of the game is speed, some operations are still aided by associates.

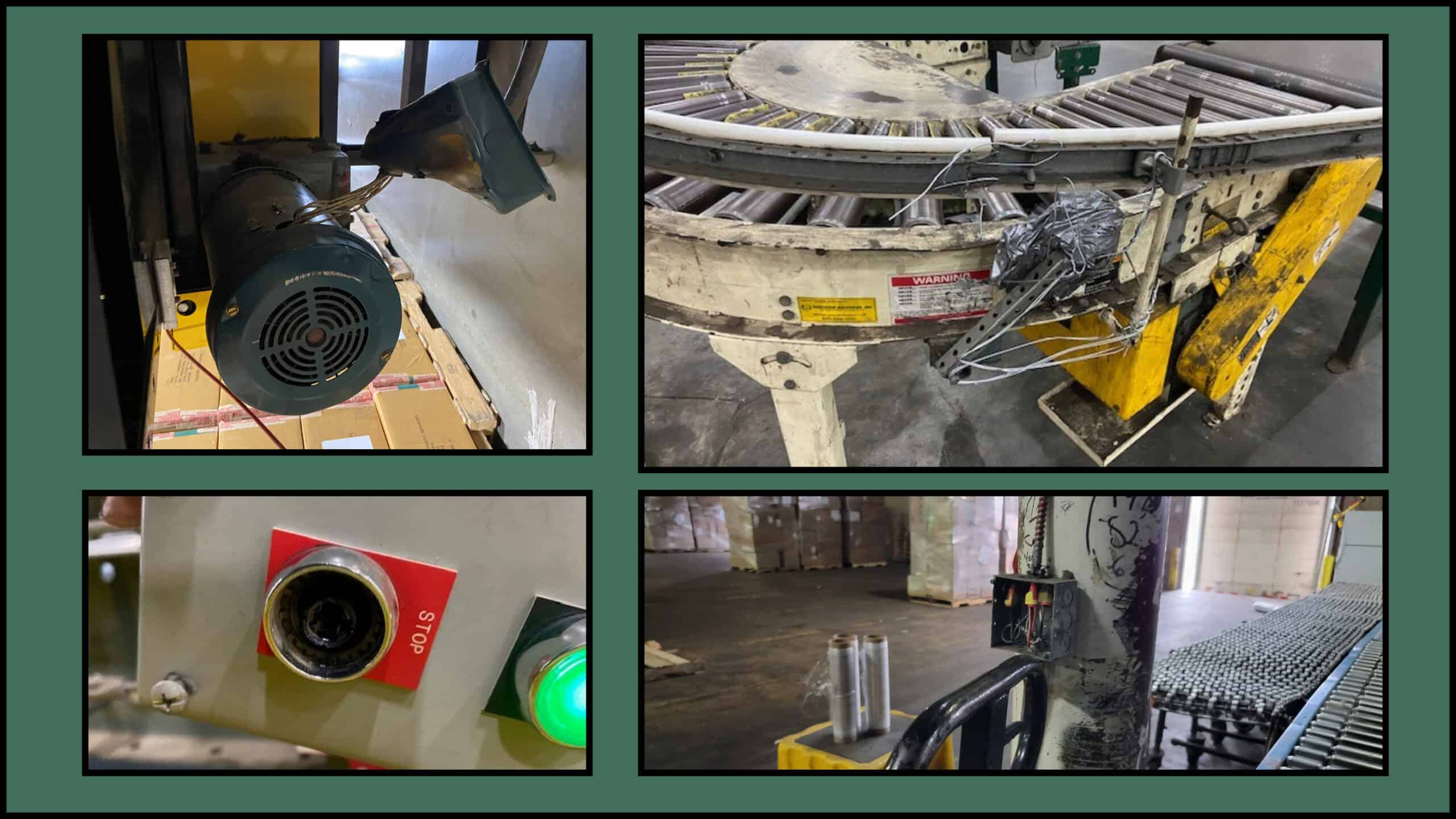

For example, in a recent crossdocking system Century integrated, a Eurosort split-tray sorter was used to handle polybags and crushable soft packages. As the polybags transition from the receiving conveyor line into the sorter, a chute drops the parcels to a short gravity conveyor adjacent to the sorter. An associate takes the parcels and places each one completely flat with no overlaps into its respective tray.

The bomb-bay tray style allowed for 2 small polybags, or 1 large one. Once on the tray, the sorter conveys over chutes, opening the tray down and dropping parcels into the correct destination box.

Sortation

In this phase, goods are sorted according to their end destination. This sorting can be based on criteria such as product type, customer order, or shipping destination. Efficient sortation ensures that the right products are matched with the right outbound orders, reducing the chance of errors and delays.

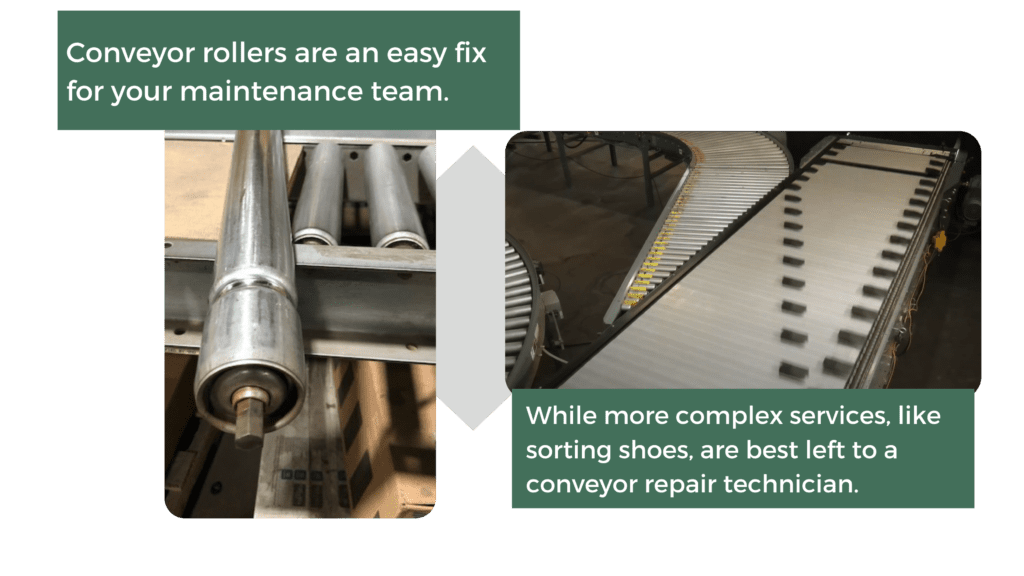

The type of sortation equipment should be driven by the size of the carton and throughput required to make rate. Small or thin parcels should consider a belt-driven sorter, with rollerball or modular diverts to destination lines. The belt ensures that smaller parcels can’t slip or get jammed in between rollers (which could happen with a gravity solution). Cross-belt and tray sorters are ideal too, as the platform moves rather than the package itself, effectively eliminating jam points.

Midsize to larger packages benefit the most from a roller gravity or slat sorter, as it provides greater speed without concern of stuck packages (like smaller or larger parcels could). Skatewheel, roller transfer, push bars, and plastic shoes are ideal divert methods, and the angle of the divert can be as sharp as 90 degrees. This product size is the best use-case scenario for a crossdock system, as high throughputs can be reached while maintaining stability.

The system used in the video is a Hytrol ProSort – a popular choice for shoe sorters.

Large and bordering on non-conveyable items may need extra care when selecting sortation equipment. Singulation equipment or associate interaction may be required to carefully place large cartons on conveyors inducting to sorters, as improperly placed items can easily snag on transfers, edges, and diverts. Narrow-belts work well at a certain speed, as do push bar and modular diverts. The transition after the diverts should be at a gradual curve – 30 degrees is a common recommendation.

Shipping & Loading

Once sorted, the goods are loaded onto outbound trucks, ready to be shipped to their final destination. Again, speed is key. By minimizing storage time and keeping products moving, companies can dramatically reduce shipping times, improving customer satisfaction and slashing operational costs.

Much like receiving; end-of-line extendables (an Adjustoveyor for example) telescope into an empty trailer to aid workers with loading. If sorted cartons are being palletized, a robotic arm palletizer and an automatic stretch-wrapper can be deployed to quickly build pallets.

There does exist autonomous trailer loading, in the form of large AMRs that can load and unload multiple pallets, and with conveyor-robot arm hybrids (such as Mujin’s TruckBot). This technology is still in its infancy, and prices reflect this, but fully automated trailer loading is no longer a far-off thought of science fiction.

The Benefits of Crossdocking

- Reduced Storage Costs: Since goods don’t sit in a warehouse, companies save on storage fees and the overhead associated with managing large inventories.

- Increased Efficiency: By streamlining the flow of goods, crossdocking eliminates unnecessary handling steps, speeding up the process.

- Improved Throughput: Faster processing times mean that more orders can be fulfilled in less time, increasing the overall capacity of the logistics network.

- Lower Risk of Damage: With less manual handling and storage, there is less opportunity for products to be damaged or misplaced.

- Enhanced Customer Satisfaction: Faster shipping and fewer delays lead to happier customers, which is crucial for maintaining a competitive edge in today’s market.

- Maximize Automation: The nature of crossdocking lends itself perfectly for integration with automation systems. Once a case is received, it typically doesn’t need to be touched by an employee until trailer loading. The upfront investment can be a large pill to swallow, but that investment will quickly return based on the increase of orders and the speed of processing.

- Eliminate Manual Labor Roles: With proper automaton integration, the woes of finding and successfully hiring associates is drastically decreased. Certain roles may be completely eliminated – saving money allocated towards payroll, hiring, and training. In the event of the obsolescence of forklifts (or several of them) because of automation deployment, the equipment can be sold or used at another facility in the network.

Should I Implement Crossdocking?

While crossdocking offers numerous advantages, it may not be the best fit for every operator. Since order fulfillment, goods-to-person, and storage are mostly absent from crossdocking operations, any facility that manages those processes may not benefit from a crossdocking setup

It works particularly well for companies that:

- Handle perishable goods that need to move quickly through the supply chain (e.g., food, pharmaceuticals)

- Distribute high-demand products with predictable order patterns

- Have a strong logistics infrastructure that supports quick turnover and high throughput

Industries like 3PLs, last-mile, extensive eCommerce operators, and large retailers with multiple locations are ideal candidates for crossdocking.

Century Conveyor has significant experience in developing, engineering, installing, and validating crossdocking systems. Interested in a system? Contact a Century Automation Expert to start planning yours, or explore the range of solutions we can implement in your facility.