Fast food: the winning recipe for distribution automation

In the food product distribution world, precision, timing, and freshness are everything. The difference between an optimized operation and a costly bottleneck often comes down to how product flows through the facility.

Automation and properly engineered material-handling systems for this segment are no longer a suggestion – it’s the only way to continue growth.

Food distributors contend with a variety of challenges: tight margins, high SKU counts (including fresh, frozen, ambient, seasonal, private-label, and multiple product counts/sizes), multiple temperature zones, complex fulfillment patterns, labor constraints, and regulatory traceability and food-safety demands.

Century Conveyor integrates turnkey systems to address exactly these conditions.

The state of food distribution for 2026

Food processing and distribution face a series of unique challenges, and as global trade and economic headwinds impact every sub-category of the food supply chain – operators are searching for solutions to the top pressing issues.

- Labor shortages and rising costs: Hiring, training, and retaining affordable and reliable labor is a significant challenge for the food industry. Proper operating and safety procedures are paramount for a warehouse associate to learn to avoid damages, errors, or unsanitary situations.

- This can affect certain food segments more than others. Specific types of seasoning and spices cannot be grown commercially in the US. Vanilla, for example, is primarily grown in Madagascar and requires controlled temperature ranges and hand-pollination techniques (Supply Chain Dive).

- SKU proliferation & mixed-temperature flows: Food distributors are carrying more product lines now than ever. More SKUs – mixing ambient, chilled, frozen, varied sizes and counts, private-label, promotional items, and organic/specialized products.

- Regulation, traceability & perishability: The need and ability to track lot codes, monitor temperature zones, ensure first-expiring first-out (FEFO) and detailed order documentation for each shipment.

- Customer expectations: Restaurants, grocers and convenience chains expect faster turnaround, tighter route accuracy and highly customizable orders. Margins can be very thin for these segments, so the ability to shift to alternative ingredients/products for cost-effectiveness is a must for a distributor’s client.

- Network optimization: Many distributors are consolidating towards a regional automated warehouse method. Instead of operating 2 or 3 sites that are mainly manual processing, a larger greenfield site designed automation-first can make up the difference operationally.

- As an example: Walmart’s fresh food segment invested into an automated DC sized at over 700,000 sq ft, utilizing storage/retrieval and robotics to manage high-volume fresh product flows (Supply Chain Brain).

Automation equipment that food distributors are integrating

Here’s how Century orchestrates the optimal solution equipment, automation strategy, product handled, facility constraints, and real-world processing flows – all in an effort to achieve and surpass key performance indicators.

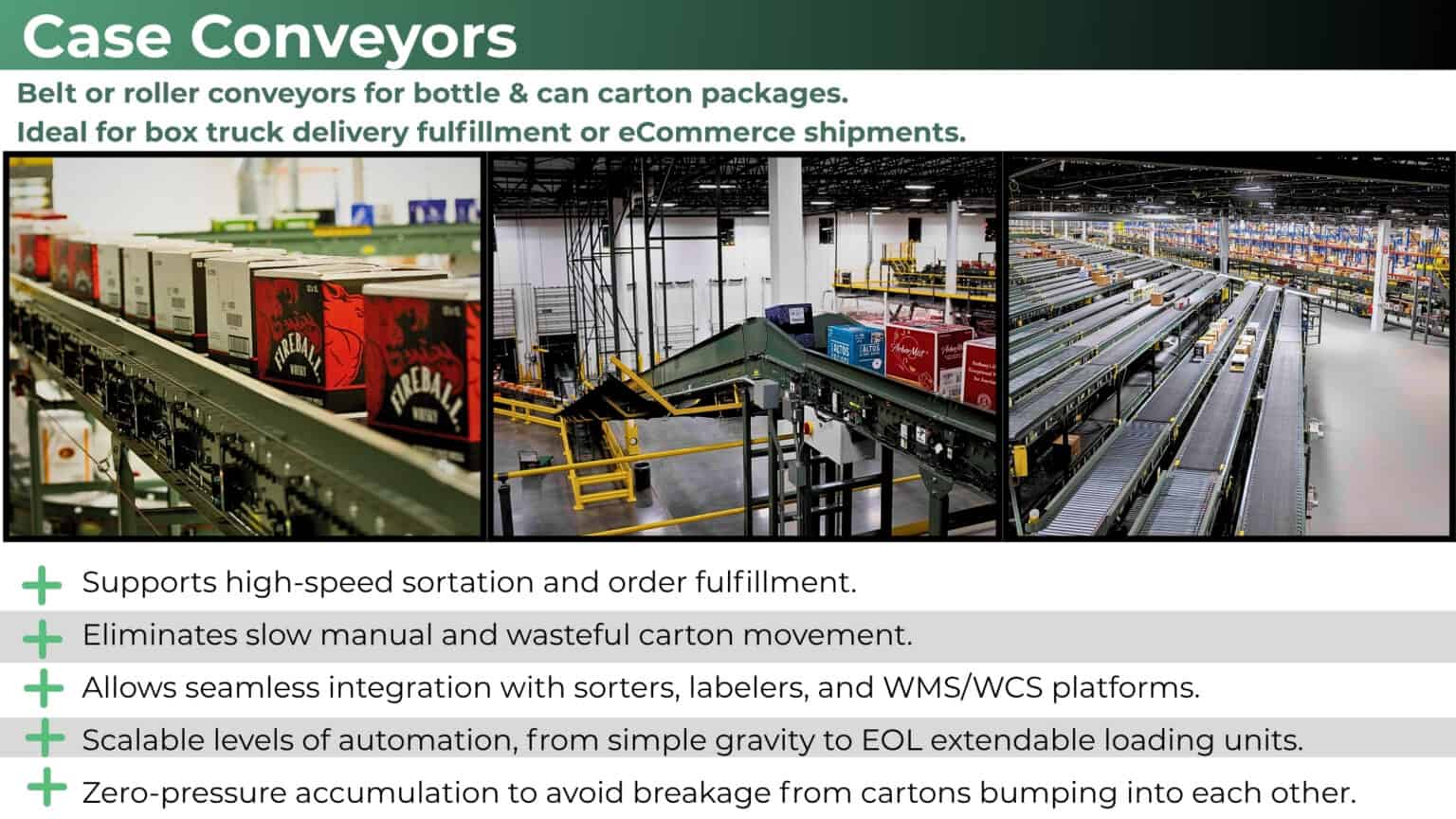

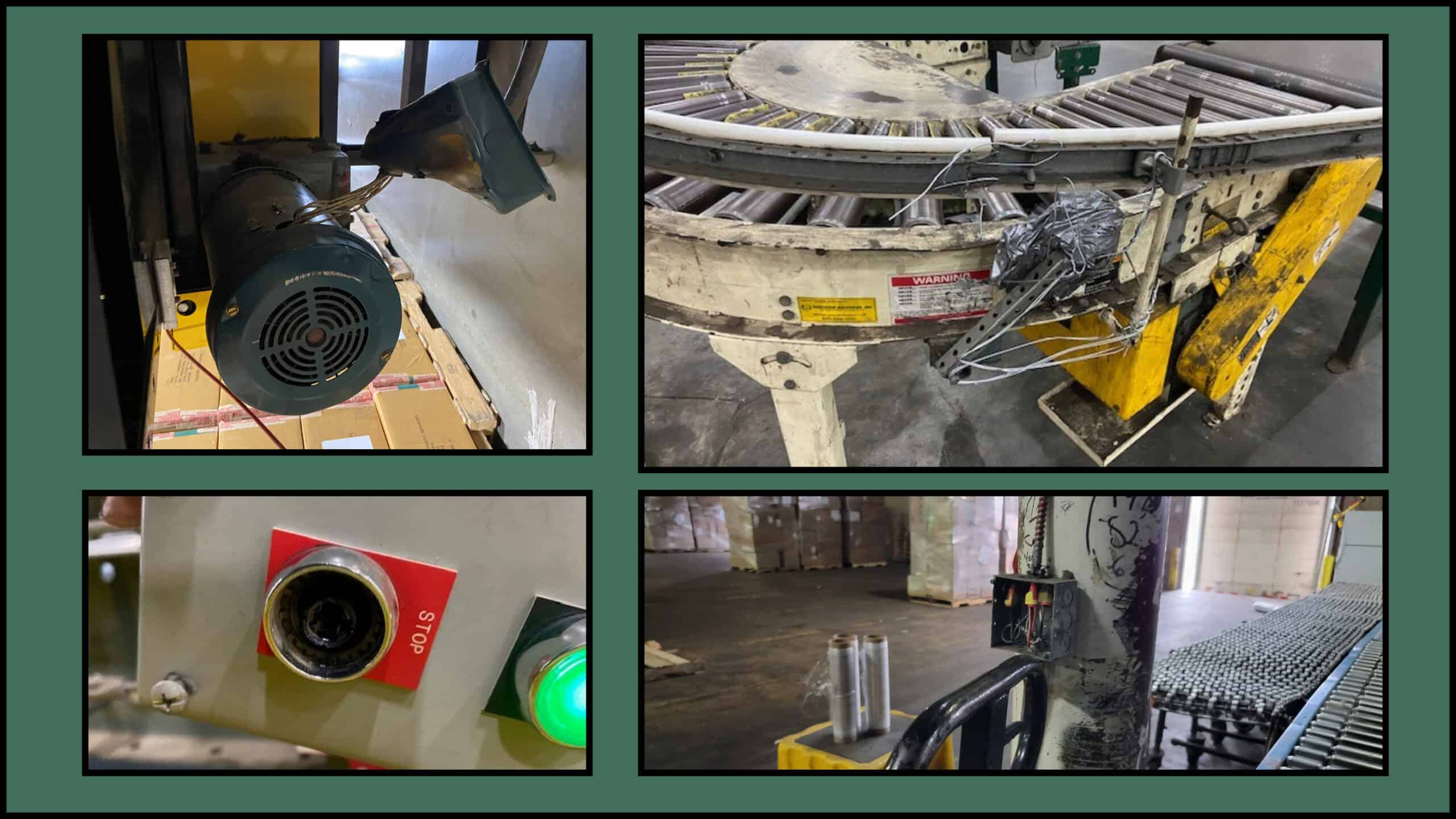

Case & Tote Conveyor

Use case: Cooler, freezer and ambient sections receiving bulk pallets, moving totes/cases across zones, staging for picking. Standard conveyor belting/rollers can be utilized for movement of ship-ready packages, but items in their shelf-ready packaging (or anything prior) must use stainless steel or washdown units.

Usage

- Bulk inbound movement of cases/totes from dock into storage or picking zones.

- Transfer across temperature zones (ambient → chilled → frozen) with appropriate conveyance.

- Stainless steel and washdown may be required for products not already in a shipping-ready container (shrink-wrapped styrofoam tray meat products, produce bags or plastic containers, totes that hold raw product, etc.). These operations take place upstream before material-handling packaging/storage/shipping EOL processes.

Benefit

- Mitigates labor-intensive manual movement in complex, regulated (and often proprietary) operations.

- Minimizes product handling by reducing damage and exposure to temperature variation.

- Seamlessly connects food processing operations to packaging/shipping processes.

Zero-Pressure Accumulation & Buffering Conveyors

Use case: Outbound staging for mixed-temperature loads, wave processing, picking and fulfillment operations. Zero-pressure and buffering conveyors focus on creating a space between items to minimize damage and

Usage

- Staggering cases/totes avoids product touching during conveyance.

- Accumulation can be based on route or customer needs (mixed-SKU orders, palletizing, etc.).

Benefit

- On-the-fly adjustment for seasonal spikes or demand fluctuations.

- Reduces damage/case crush and jams.

- Prepares sequence for outbound ops, improving dock consistency and load times.

Automated Sortation

Use case: Consolidating mixed SKUs, directing cases by customer, route, temperature zone. Sorter units utilize different divert methods based on throughput and type of product handled. These can take the form of sliding shoes, belts, trays, chutes, sweeping arms, skatewheels, and more.

Usage

- High-speed diverting of individual cases or totes into correct outbound lanes (for ambient, chilled, frozen).

- Enables sequencing for ease of load or pallet-building

Benefit

- Enhances order accuracy and trailer-build reliability.

- Enables faster loading with reduced manual sorting.

- Supports multi-temperature loads with minimal error.

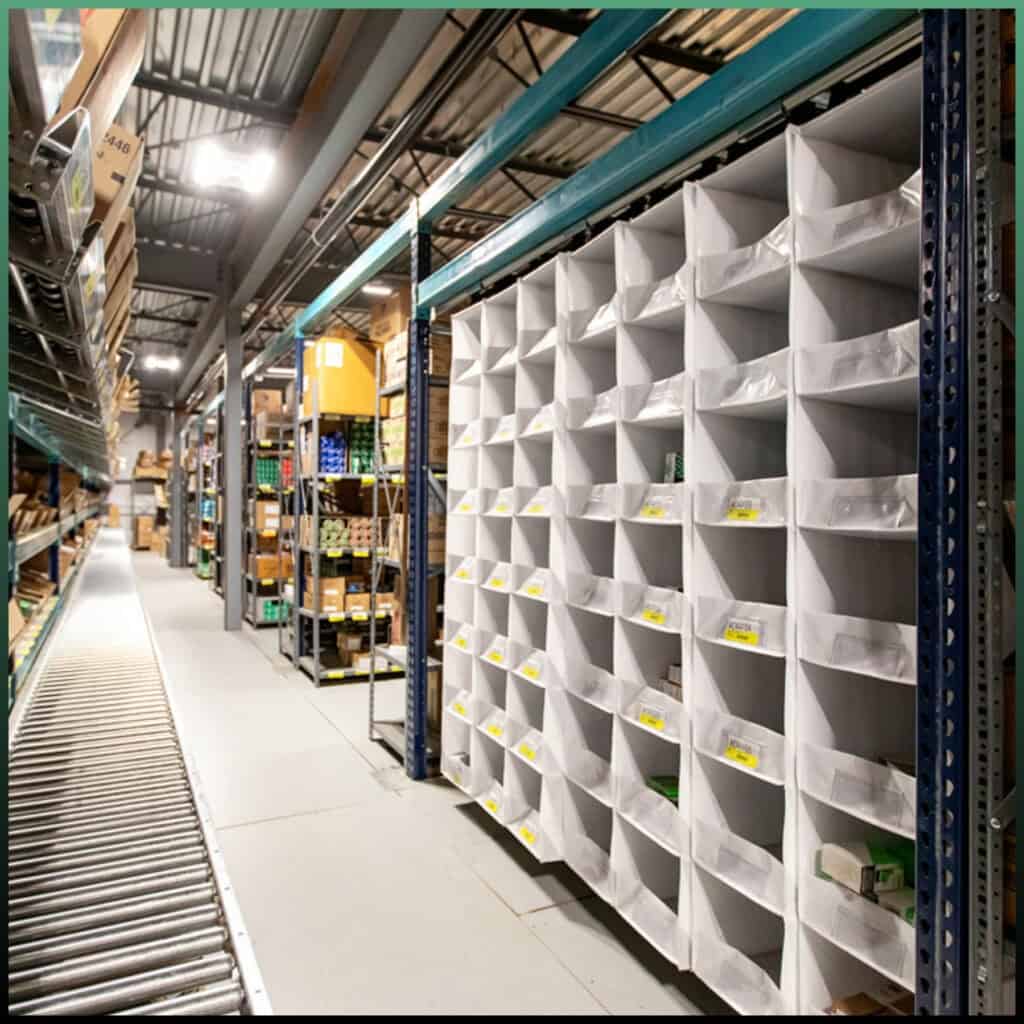

Pick Modules & Goods-to-Person Systems

Use case: High-mix picking environments (specialty items, private-label SKUs, promotional packs, various sizes) and omni-channel flows for distribution.

Usage

- Pick modules can come in the form of picking shelves, flow rack, cobots, robotic arm cells, or AS/RS.

- Pickers select the order items from the manifest and outfeed cases/totes onto conveyors, robots, or GTP units.

- GTP workstations enable order fulfillment, but most food distributors may use pallet building automation (such as a layer-building gantry unit) as items are bought in bulk rather than singular quantities.

- Typical GTP operations in a large food distribution facility has associates stage items so pallets can be built.

Benefit:

- Improves picks per hour, especially for complex orders.

- Lowers labor burden and error rates.

- Scales consistently when SKU counts rise.

- The level of automation deployed can be engineered to current processing rates. A smaller food distributor might not have the CPM to justify the cost of an AS/RS.

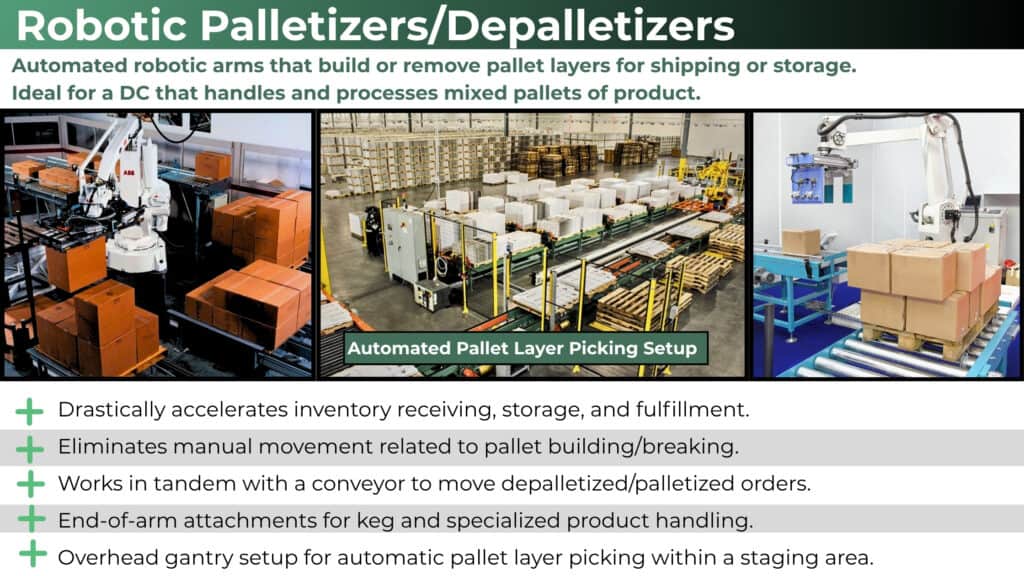

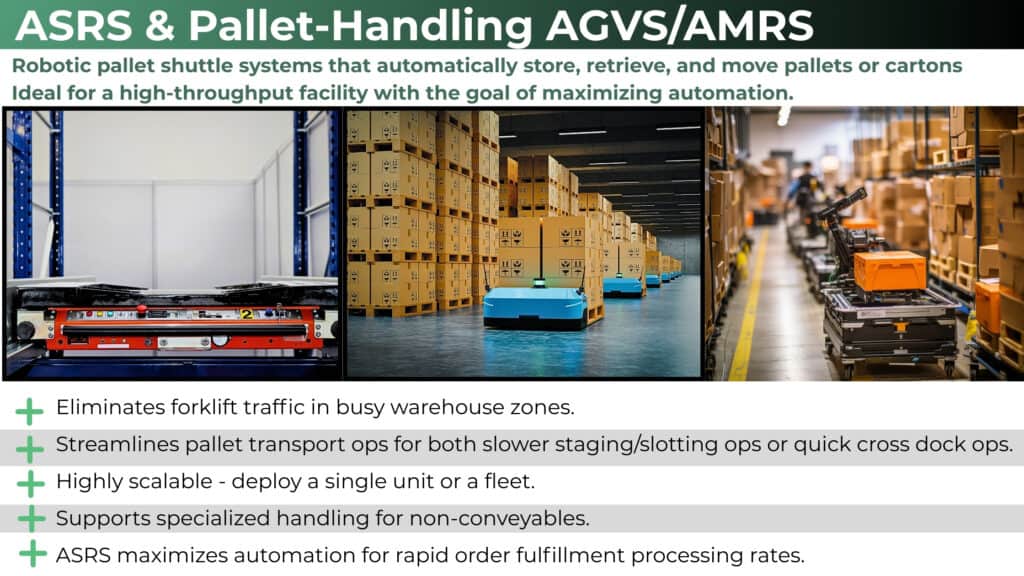

Palletizers & ASRS

Use case: High-density storage (especially chilled/frozen), inbound bulk pallet breaking, outbound pallet build by route.

Usage

- AS/RS cranes/shuttles in cold zones handling pallets with minimal manual intervention.

- Robotic layer-picking or pallet build for mixed-SKU outbound loads.

Benefit:

- Dramatically increases storage density (critical when floor space is expensive).

- Removes labor from the coldest, most injury-prone tasks.

- Speeds build of outbound pallets in sequence for trailers.

For example: A distributor extended the life of an existing DC by 10+ years using an AS/RS and layer-pick build solution. (MMH)

Temperature-Zone Transfer & Traceability Systems

Use case: Cold chain integrity, tracking lot codes, expiration priority enforcement.

Usage

- Conveyors and systems designed for temperature-zones (ambient, refrigerated, frozen, minimal door-open time).

- Seamless storage and retrieval that avoids gaps between zones.

- WCS/WMS integrated scanning of lot/expiration info and real-time monitoring of product in zone.

Benefit:

- Protects product quality and shelf life (critical for perishables).

- Supports compliance, traceability and recall ability.

- Enables more accurate planning and lowers waste.

Real-world results: What’s working for food distributors

- Conveyors, AS/RS, robotics and automated labeling are critical to seamlessly connect operations from reception and sorting of goods all the way through palletizing and staging for chilled product flows. The longer a product sits, the more cost it accrues.

- The largest sources of inefficiency for food distributors typically take the form of damaged or past-expiration foods. Automation can store and process orders quickly to avoid perishable waste, while providing stable movement that avoids damage that could occur with manual touchpoints.

- Automated storage and retrieval systems (AS/RS) proves highly effective for food distribution operations. Large distributors have thousands of product types that require fast, yet gentle processing. Mixed-SKU orders can further complicate picking and fulfillment – and if a facility running multiple dock door lines handling a variety of transport options (LTL, local box truck, couriers, etc), it’s easy to see why many are deploying AS/RS solutions.

- On traceability/data and operational integration: Many food-distribution companies face legacy systems, disparate or unattributable data and lack of automation. Automation connects the physical to the digital by integrating reception, tracking, lot inventory management and outbound flow.

How can Century automate my food distribution operation?

- Industry-specific expertise: Our systems are designed for food distribution realities – SKU mix, temperature zones, variable pack types, perishables.

- End-to-end solution: Mechanical design, controls, integration, software and installation and service support under one roof. Selecting a turnkey A-to-Z integrator like Century can avoid an overly-complicated system implementation in which equipment doesn’t work in tandem, but in a silo (a Frankenstein, we like to call them).

- Scalable & modular design: We build for your current throughput and product handled but engineer dynamic variances for SKU growth, product type & size, seasonal peaks or future lines.

- ROI-driven: Given tight margins in distribution, our focus is on labor reduction, error minimization, space optimization, waste elimination and equipment selection that fits your budget and goals. Century focuses on building the most optimal system, not the most expensive.

Contact Century

Ready to engineer your next-generation food distribution system?

If your food distribution or wholesale operation is wrestling with escalating SKU counts, labor shortages, trade and tariff headwinds or delivery-accuracy demands – Century Conveyor should be your next consideration

Our team of automation experts, engineers, and project managers will lend their extensive knowledge and skillset to help you and your organization in paving the way to a truly optimal automated food distribution facility.