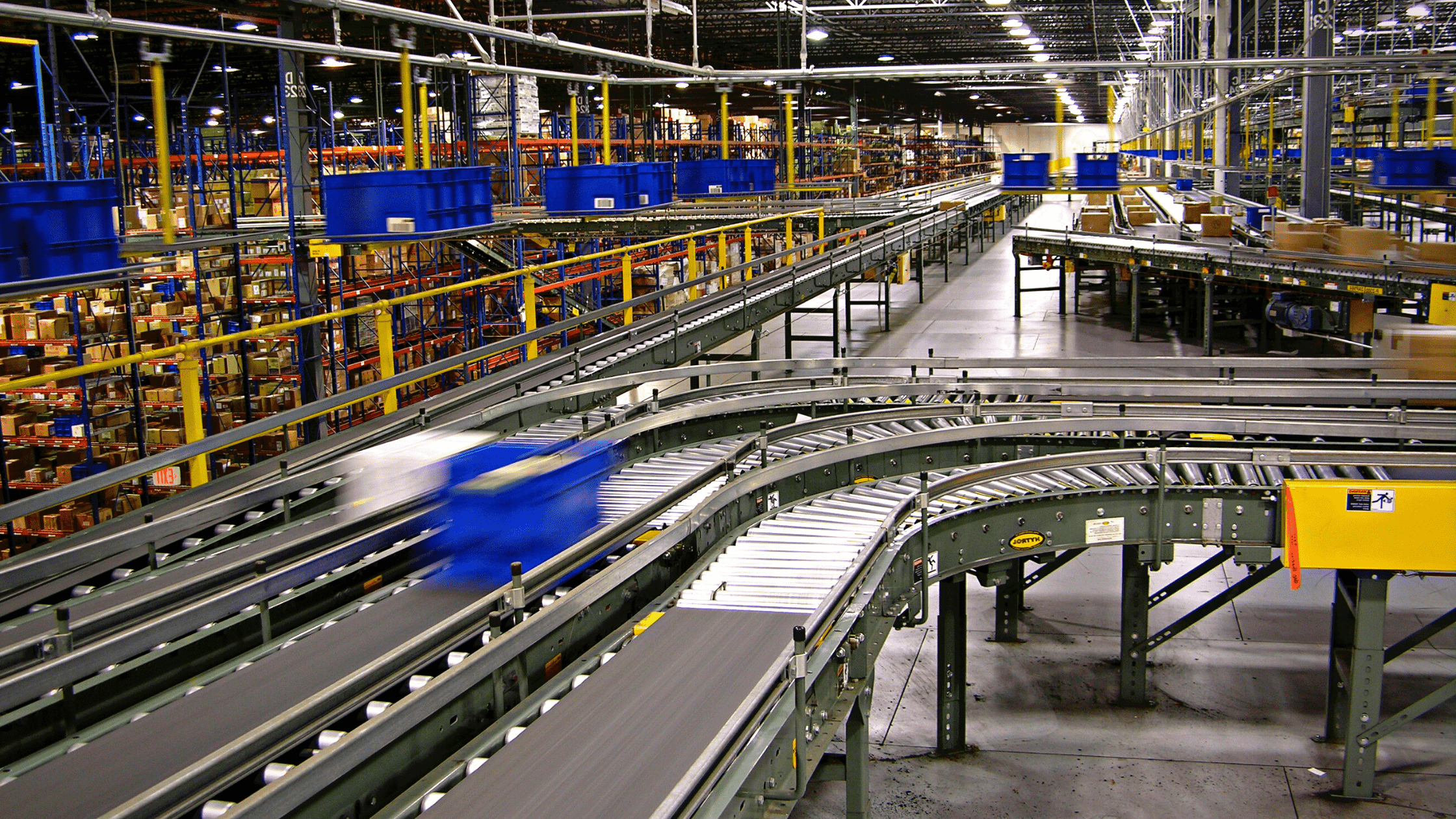

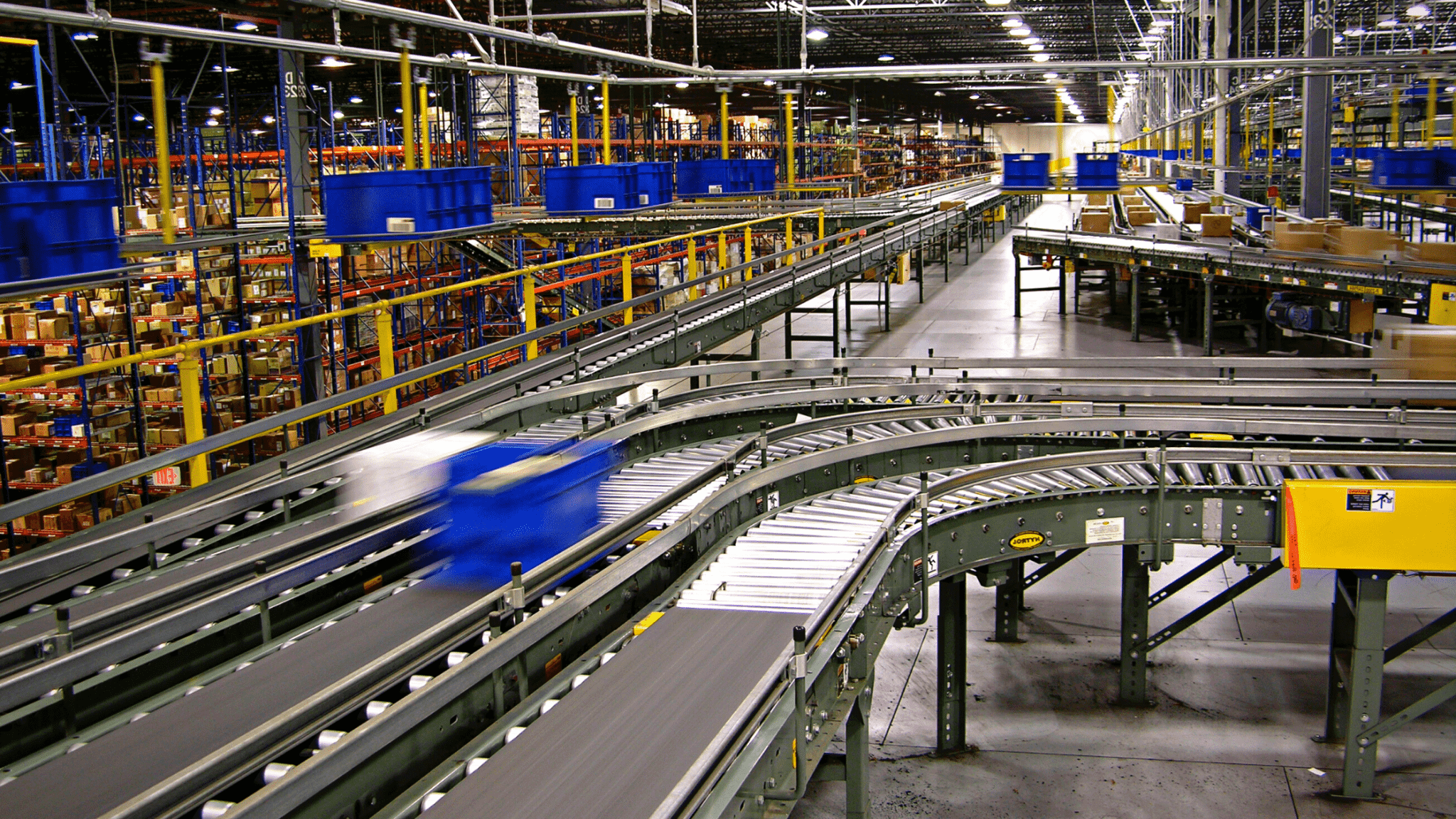

Conveyor systems are versatile machines, working in tandem with a variety of material handling solutions, ensuring increase output and productivity. Besides the additions of machines in conjunction with a conveyance solution, there exists extended automation for the conveyor system itself.

Belting plays a critical role in how the product moves throughout the system, but typically, most operations use either a roller conveyor or a flat belt. What many do not realize is that belting can be upgraded to automatically position cartons in a way that simplifies various induction steps in the line.

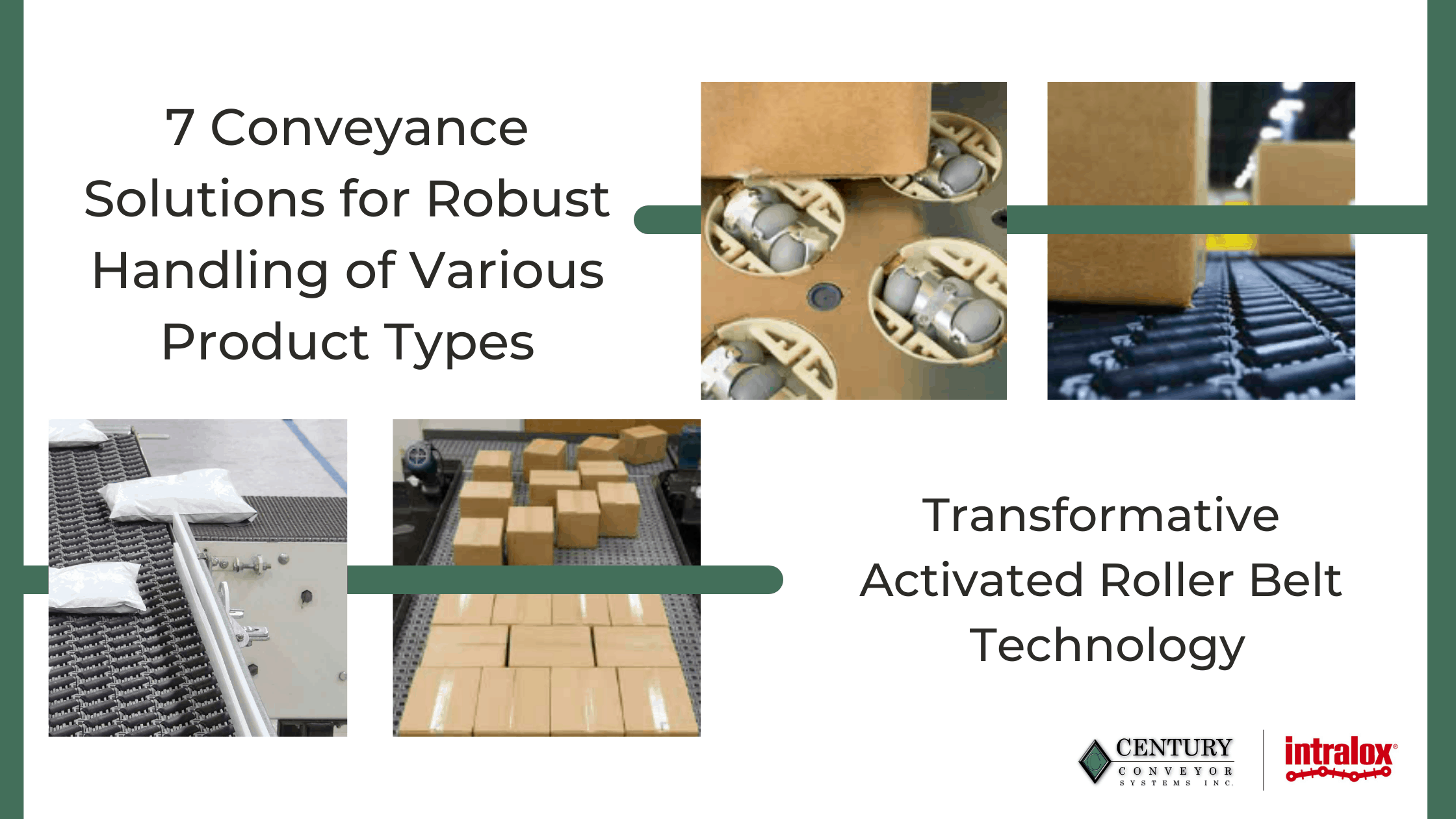

ARB (Activated Roller Belt) technology revolutionizes the way a conveyor system functions by offering automatic aligning and positioning, precise gapping, high-speed sortation and diversion, uniform operator station package distribution, and more.

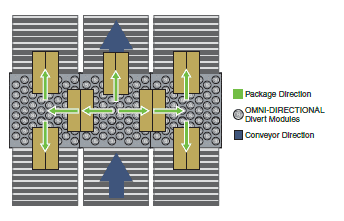

ARB equipment performs a variety of different functions on the product by utilizing free-spinning rollers that are embedded in plastic belt modules. The rollers can bi-directionally manipulate products in a variety of different angles and trajectories. The rollers can be bi-directional or omnidirectional depending on the usage of that specific belt space. The rollers reorientate themselves rapidly depending on the destination of the package.

ARB equipment can provide substantial throughput benefits while providing a quick return on investment by eliminating time-consuming manual labor and being flexible enough of a solution to apply to a variety of operations.

- Sortation

- Depalletizing

- Singulators

- Merges

- Switching

- Zone Picking

- Infeeding and Outfeeding

1. Sortation Systems

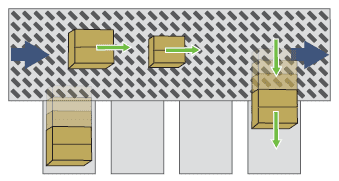

90-degree sortation

Bi-directional right-angle sortation that activates the belt rollers when the carton reaches its divert destination. This form of sortation is high speed, with rates up to 250 packages a minute, in a compact footprint. If your facility distributes a variety of packages, this sortation method can accommodate polybags, crates, top-heavy items, and more, along with typical flat-bottomed cartons.

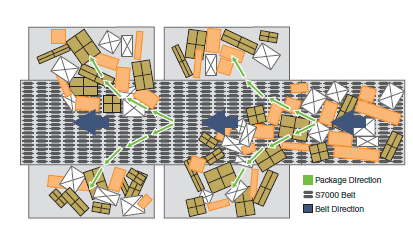

Bulk sortation

In facilities where a continuous flow of a mix of bulk packages is present, ARB equipment can be employed to sort an even volume of packages for downstream processing (operator stations, for example). Due to the bulk nature of the continuous induction, sortation rates can achieve up to 360 packages per minute, automatically avoiding jams.

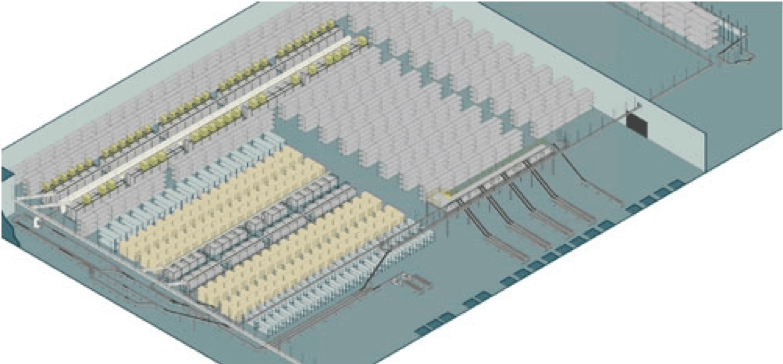

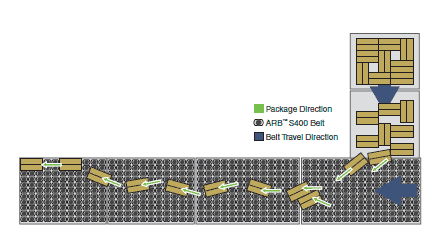

2. Depalletizing Systems

Depalletizing can be a laborious operation if done manually. With ARB equipment in use, omnidirectional track rollers can descramble up to 6 pallet layers per minute and place them in a uniform line, ideal for scanning or picking. By alternating packages left and right on the ARB conveyor, and using the side railing as a guide, packages line up neatly for downstream applications.

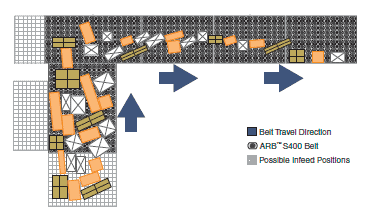

3. Singulators

Singulating, in this context, means to place the items in a single, congruent line. Depending on induction rates, this could be a continuous line, or broken up into segments (for example, one segment having four packages). ARB equipment moves the undistributed packages from left to right to acquire a straight line, using the railing of the support to gently align the items. This eliminates the need for manual clearing of side-by-sides, recirculation due to miss-sorts, and enables workers to place items on without concern for positioning.

4. Merges

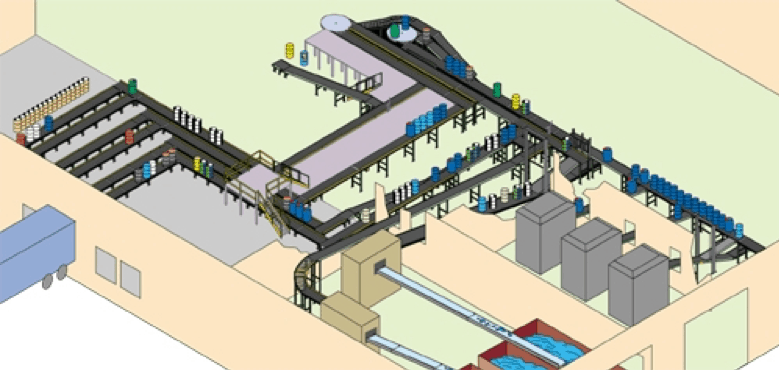

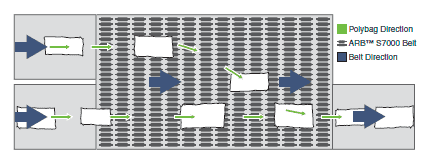

Polybag merging

In a polybag-focused operation, reliable merging from multiple infeeds is paramount to downstream processes. ARB conveyor solutions merges infeed conveyors with a high-speed directional belt, while maintaining gapping, and alignment, for later scanning and sortation operations. All of this is completed in a relatively small footprint, as an ARB conveyor is designed to quickly merge the lanes.

5. Switching

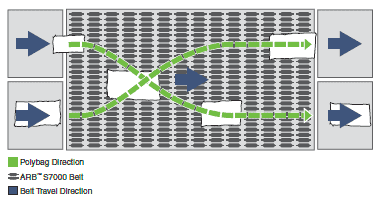

Polybag destination switching

If lanes are not merging, but instead, crossing polybags over each other to their reach their destination lane, an ARB conveyor solution can achieve this efficiently. Much like the merging ARB conveyor, omnidirectional rollers quickly switch polybags into their respective destination outfeeds, while maintaining proper gapping and alignment.

6. Zone Picking

Pick and pass order fulfillment zones can also benefit from ARB equipment inclusion. Manual picking stations can be added to a central conveyor merge, utilizing an omnidirectional sorter to easily pick packages from the main line to be processed, and then re-introduced back to that same conveyor. Order fulfillment can be completed at rates greater than 25 packages per minute, and only needs one 24-volt motor to drive the rollers.

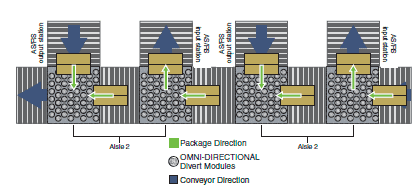

7. Infeeding and Outfeeding

Used in conjunction with an automatic storage and retrieval system (AS/RS), this ARB conveyor combines both infeeding and outfeeding operations. Packages can both be sent to storage, while simultaneously accepting packages coming from storage. This is achieved by utilizing omnidirectional sorters in conjunction with right angle diverters, with alternating flow directions that activate depending on the carton’s destination. Sortation can achieve excess of 30 packages per minute, while infeed/outfeed rates to an AS/RS can reach 1,800 cases or totes per hour.

Intralox equipment has been successfully implemented by retail, grocery, manufacturing, and direct-to-consumer e-commerce distribution centers. The technology brings value in many applications ranging from high-speed 90-degree sorting to AS/RS infeeding and outfeeding. From increased throughput to flexible package handling and efficiency, Intralox’s conveyance technologies pick up where traditional technologies end.

Century is a longtime partner and integrator of Intralox, utilizing its innovative ARB equipment technologies throughout a wide range of clients. Together, a truly efficient system can be designed, engineered, and installed to increase output, accuracy, and ROI.