Background

Capital Candy’s history dates to 1938, when a couple from Montpelier, Vermont, opened a penny candy operation from their home. Over time, the operation offered new product lines, became incorporated and expanded into new territories.

Today, Capital Candy operates six days a week, 24 hours a day to provide grocery and convenience store products to 3,000 customers across six states. “We pick, pack and deliver 55,000 packages a week. Our trucks make 33 trips every night,” says Jim Thibeault, Operations Manager.

The operation houses mostly perishable items, such as dry grocery products, frozen and refrigerated foods, and non-food items, such as tobacco products. As the demand and variety of SKUs increased in the tobacco category, Capital Candy decided to design a new addition to house all tobacco-related products. But to make room for an ever-growing and ever-changing line of inventory, the operation required optimal storage, picking and replenishment solutions.

Challenge

Growth is great for business, but it can put a squeeze on space at the warehouse—which is exactly what happened at the Capital Candy operation.

“We’ve been fortunate to have increased sales every year for the past 15 years. But when COVID hit, many restaurants shut down, and convenience stores got very busy, which meant our SKUs had to increase too,” says Jim. “At one point, we were over 140% full in two regions of our warehouse. We had to do something.”

Capital Candy had two options: Find another warehouse and move, or build onto the existing facility in Barre, Vermont, where the operation had serviced customers for nearly 50 years. Capital Candy chose option two and got approval from the town for a 60- by 100-foot addition measuring 26 feet high to the warehouse.

Goals

- Maximize pick areas for fast movers

- Deploy high-density storage for slow movers

System Specifications

- 27-bay UNEX SpanTrack Wheel Bed

- 196 slot, 2 bay UNEX SpeedCell

- UNEX Gravity Conveyor

- 287 sq. ft. steel work platform

Integration

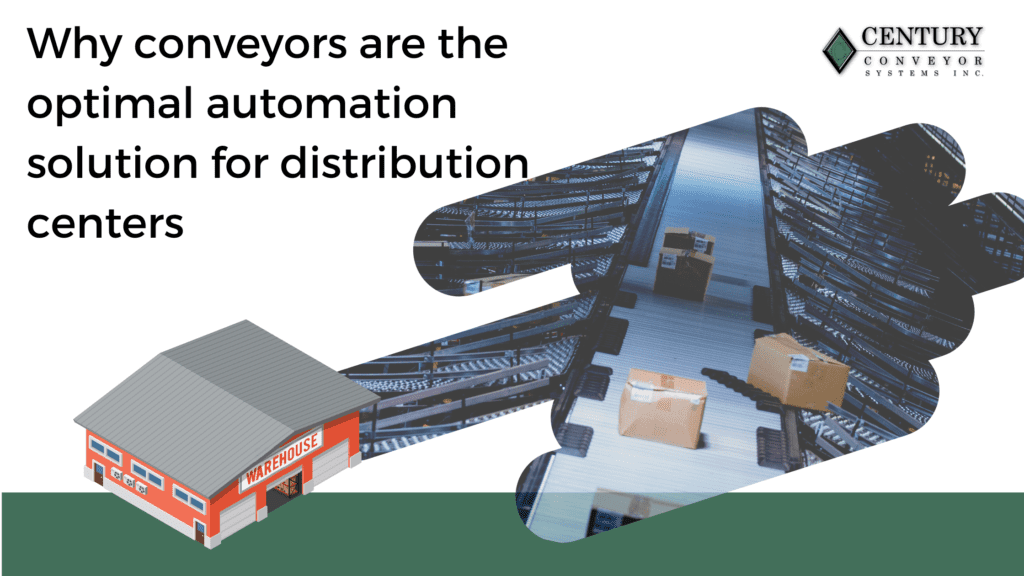

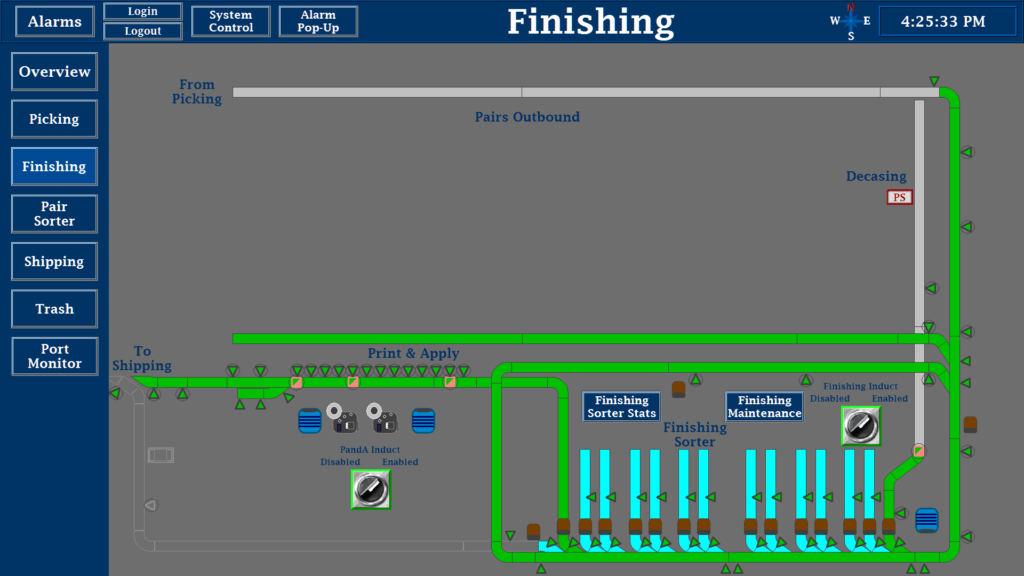

Century Conveyor Systems utilized UNEX conveyor and equipment to integrate flawlessly with the exisiting UNEX roller rack, shelf track, and roller bed. Century installed 27 bays of SpanTrack Wheel Bed with four levels in each bay or 108 total levels of carton flow.

“The Wheel Beds are great because they make picking and replenishing easy. It will never be hard for them to re-slot the flow rack again,” says Dave Mydlowski; senior engineer from Century, who worked with Capital Candy and UNEX to design and implement carton flow solutions at the site. “And the quality of the product is excellent, durable, reliable.”

SpanTrack Wheel Beds drop easily into structures to create the ultimate flow rack system for full-case and each-case picking. The system is highly flexible, sturdy and provides carton flow for products of various sizes and weights. And because SpanTrack Wheel Beds provide 300% more product contact than plastic wheel rails, hang-ups are eliminated.

“With the new solution, efficiency was up immediately on day one—greater pick density, fewer steps, less climbing and better product storage,” says Jim.

Century also added two bays of SpeedCell and Gravity Conveyor in both downstairs and upstairs pick areas. SpeedCell provides high-density storage and can compress 200 feet of rack or shelving into 40 feet of highly organized space. More pick facings and greater SKU density mean less travel time and faster picks and restocking.

Results

The Wheel Beds allowed Capital Candy to store 3,600 more cases of product in the location and enabled the operation to add 900 new items with room to spare. The density of the pick also reduced the number of pickers needed in the tobacco area. The same picks are now being done by 1.5 fewer pickers, which is a huge savings for Capital Candy and a win for workers too. Pickers are paid by the number of items they pick. And because the pick area is so dense, pickers can pick more items faster.

By implementing SpeedCell, Capital Candy was able to slot 196 slower-moving items into two eight-foot bays with each picking, saving the operation about 72 feet of shelf space. “We’ve used many UNEX solutions, but this was the first time using SpeedCell, and our intention is to add it to other areas of the operation,” says Jim. “The product has maximized our space, and it’s been a hit with pickers, stockers and our purchasing department.”