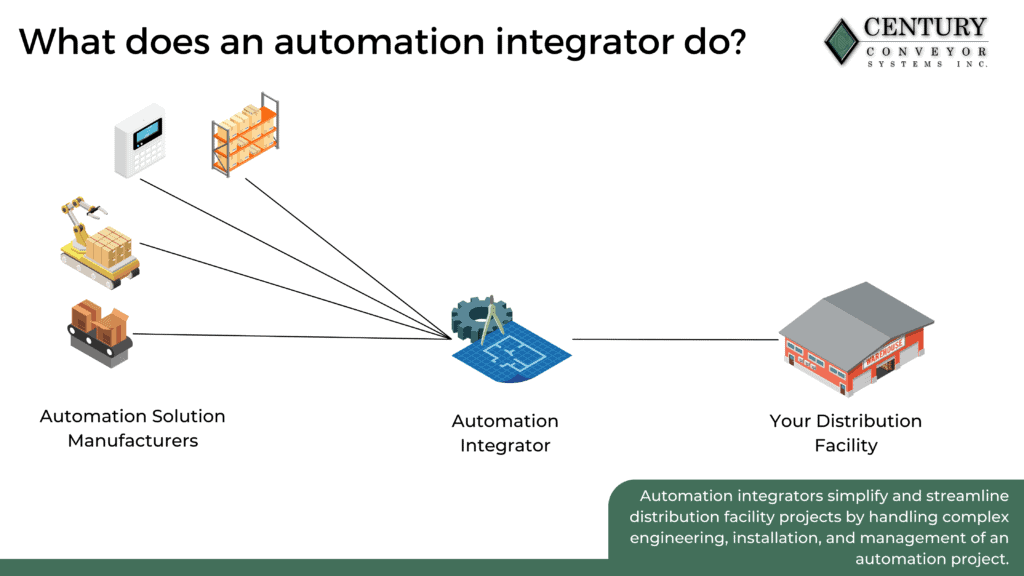

An automation or material handling integrator is a B2B service that plans, engineers, and manages system projects for a distribution facility or warehouse. Systems can span from simple racking installations to complex distribution center layouts with multiple lines. Automation integrators work closely with clients to design a system that fits their facility limitations, handled product, operational goals and needs, budgetary considerations, and return-on-investment requirements

The need for integrators began as the gap between material handling equipment and automated systems became larger and larger. Before the mainstream use of automation within the industry, integrators provided a sales and installation channel for material handling equipment. As technology advanced and consumer behaviors necessitated highly automated distribution centers, material handling integrators focused more on engineering layouts for these new solutions rather than simply selling them. Century started as a conveyor service and repair company but evolved to serve customers with automation engineering needs.

Today, industrial automation is a bustling industry, abundant with new innovations and technological advancements for the world’s increasingly complex supply chain. A few of the leaders in the automation integration space include:

This may be common knowledge for many in the industry, but not as well-known are the benefits of using an integrator versus an internal engineering team or going direct to the manufacturer.

Benefits

Project Ease

One of the most difficult parts of any project is simply coordinating, planning, and managing it effectively. This difficulty can be exacerbated exponentially if this is the first implementation project, or if the team tasked with spearheading the project are not trained specifically in industrial automation systems.

Integrators soothe the pain of planning by managing all aspects of a project on their end. Typically, an integrator will be in communication with the lead engineer, facility manager, distribution manager, or operations director on your team. Essentially, whoever has the most knowledge of your distribution center’s operations and has a clear goal with what they want to achieve with automation.

To properly quote and plan a job, integrators ask many questions, complete many site visits, and meet extensively – all in an effort to make the project move forward as smoothly as possible.

Expert Engineering

Integrators employ a team of mechanical engineers to create solution layouts. The engineers are specially trained or have a background in industrial automation and understand how to achieve an efficient system via knowledge of the systems available and firsthand experience. Most integrators will have a few engineers present during facility planning visits and installation procedures to supervise the project process.

The advantage of using an integrator is gaining access to the experience of its engineering team. After hundreds of automation projects, an integrator has distinct know-how in navigating projects, industry best practices, and intimate knowledge of cutting-edge automation solutions being offered in the marketplace. The focused approach to industrial engineering in the pursuit of efficiency is a constant throughout every integration project, whereas an internal team or singular consultant may have only a holistic idea of automation engineering.

Vendor Partnerships

Integrators, especially well-established ones, will have a sizeable network of partnerships with automation machinery manufacturers, material handling equipment vendors, control houses, software platform providers, and mechanical and electrical installers, among others. Leveraging these partnerships allow integrators specialty pricing, shorter equipment lead times, and access to valuable automation resources.

It’s in an integrator’s interest to make and maintain vendor partnerships, as many manufacturers primarily sell their automation systems to integrators, and integrators receive projects to engineer those systems (think of “if you scratch my back, I’ll scratch yours”). This benefits the end user going through an integrator, as established partnerships place a priority on integrator projects and requests, as well as receiving the aforementioned vendor perks.

If there’s a specific system that you’d like to use in your warehouse, any integrator will work hard to ensure it can be utilized effectively. But, if the engineering doesn’t work in its favor, an integrator can recommend alternative systems that closely match the function of what was originally proposed. This extends to retrofits and legacy systems.

Singular Source

With an integration, all aspects of your facility automation project flow through a single source. Depending on the size of your project, your main contact will typically be a sales engineer, and once a proposal is signed, a project manager and senior engineer will be tasked with your account. If the project warrants, an entire team of engineers may be dispatched to the facility location to oversee installation and start-up procedures.

An integrator will offer concise and transparent communication during every step of the implementation. This also includes regulatory guidance across all mechanical, electrical, and compressed air installations, as well as coordinating the proper building permits and safety standards. With the experience of working on job after job, all these standards are commonplace across integrators and come second nature when managing a new project.

Sparing yourself the headache of wrangling together the nitty-gritty of your automation project might be worth the cost of entry with an integrator alone, but still, the value of employing one increases the closer you look.

System Support and Service

While not as common among integrators as some of the other points, many employ an aftersales department dedicated to maintaining your turnkey system with parts and repair servicing. System downtime is a massive drain on time and money, and integrators understand that the majority of automation solutions are running nonstop. If even one is malfunctioning, the entire process comes to a screeching halt.

Integrators actively want to avoid this situation at all costs, so an ancillary service is offered to keep a stock of spare parts on hand, so any broken components can be replaced right away. When a project is completed, an integrator will create a log of recommended parts to have in a storage room within your distribution center. This can range from common items like motors, belts, sensors, fluids, and more, to entire automation machines that may be installed later. As durable as some of these machines are, they are still machines and need proper maintenance to operate flawlessly.

Along with spare parts, integrators may offer a preventative maintenance plan for your system. Based on your solution requirements, a service technician can be dispatched to your location to administer routine repairs and recommend when certain parts should be swapped out for newer components.

In the event of an emergency, some integrators (like Century!) have the capability to send a technician out to remedy the issue. If it’s something that can be fixed remotely, like a push-stop button reset, some integrators (again, like Century!) have a 24/7 support line that can securely VPN into a WMS/WCS system and troubleshoot the issue live.