Cheers! The ideal automation solutions for distribution facilities that handle and process a variety of beverages.

Wine, spirits, and beer distributors operate in a uniquely complex environment where high product variety, strict handling requirements, and time-sensitive deliveries converge on a daily basis.

Distribution facilities must manage a varied and ever-changing inventory that includes fragile glass bottles, bulky kegs, and diverse packaging formats, each requiring specialized storage and handling. Seasonal demand spikes, SKU proliferation from new brands and product lines, and mixed-case or mixed-layer orders add further levels of operational difficulty.

At the same time, distributors face constant pressure to maintain accuracy, protect product integrity, and meet tight delivery schedules, all while contending with labor shortages, rising operational costs, and the need to maximize throughput in often space-constrained facilities.

The current struggles of the WS&B distribution industry

- Distribution facilities are often challenged by labor shortages, high turnover, and the physical demands of repetitive manual tasks. This makes it difficult to acquire and keep reliable labor while ensuring workers are trained sufficiently on their tasks to maintain processing rates and avoid breakage

- Product loss from improper handling can cut into already thin margins, particularly with fragile glass packaging and liquid cargo that is susceptible to breakage, seepage, or spoiling. If defects go by undetected, the client will end up with damaged product which could incur a loss of business if it’s a repeat situation.

- As new products and SKU variations continue to proliferate driven by consumer demand for specialty brands, seasonal offerings, and diverse packaging formats - managing inventory complexity becomes increasingly difficult. Currently, younger markets are not consuming “traditional” beverages at the same rate as other consumers, but rather more specialized products like mocktails, energy drinks, mini serving sizes, zero-alcohol items, CBD seltzers, and more.

- Mixed-layer order fulfillment (rainbow pallet), a common requirement for retail and hospitality customers, is time-consuming and error-prone when handled manually, while traditional pallet building and singulation processes limit throughput and consistency. Storage and retrieval workflows can also bottleneck when relying solely on forklifts or manual pallet movement. The flexibility of products clients want in their orders add a significant layer of complexity, but properly engineered automation can streamline these ever-popular order requests and make sense of even the most specialized load.

- Bridging the gap between production and material handing operations can be a significant pain point for WS&B businesses that run manufacturing or filling operations. Typically, manual processing in this stage is time-consuming and inefficient since it’s difficult to time all parts of the operation without cohesive automation. Many facilities opt to keep each area siloed for control and management purposes, only processing production in a separate line or shift. Automation can connect disparate systems in a continuous, optimized, and visible solution to avoid overcomplication.

By integrating material handling automation into post-production and distribution operations, beverage companies can overcome these pain points – reducing labor dependency, protecting product integrity, efficiently managing growing SKU counts, automating complex order building, and streamlining storage and retrieval for faster, more reliable fulfillment.

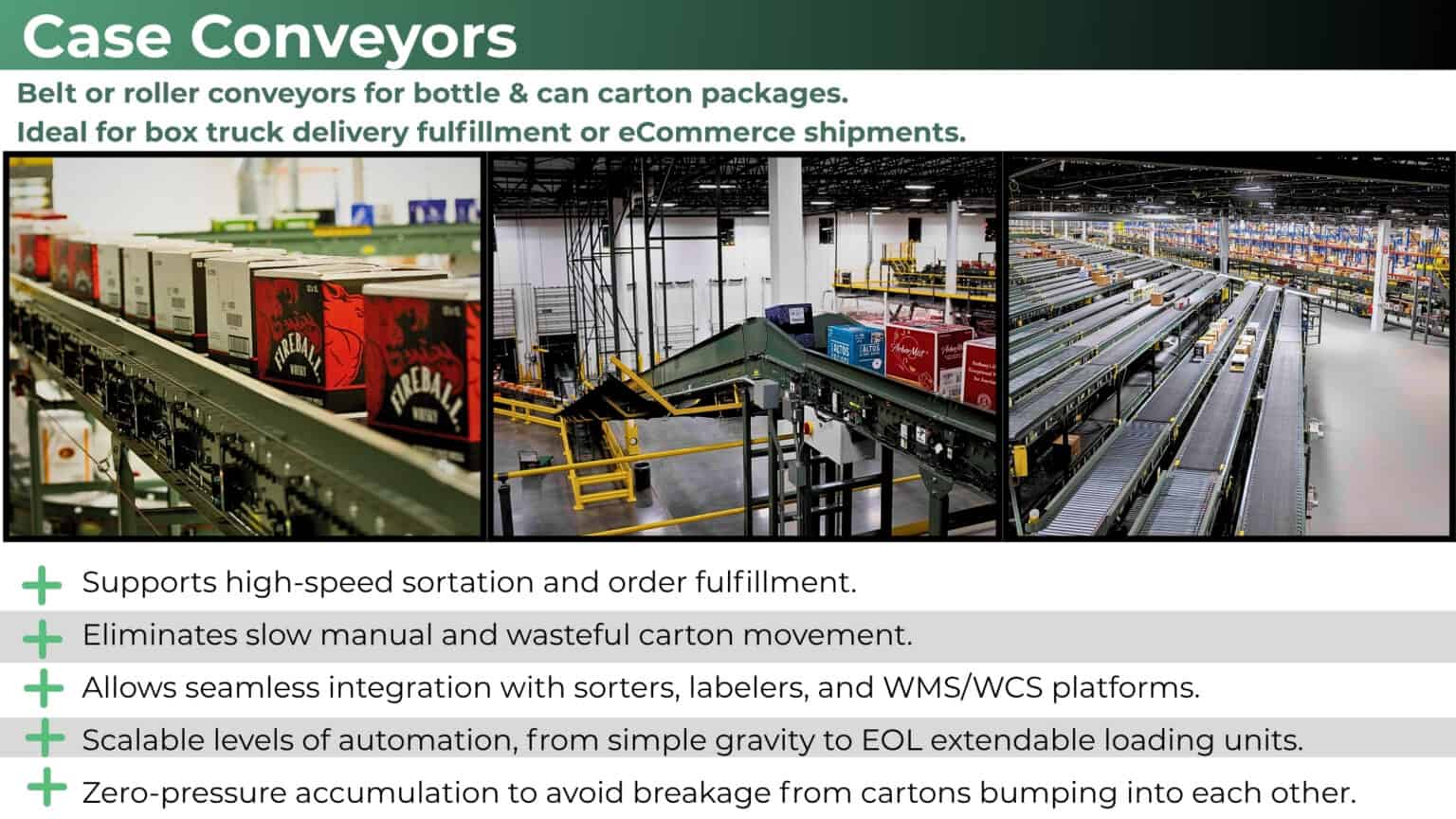

Conveyor Equipment

Case conveyors are ideal for picking and sortation zones, transporting cartons of wine, beer, or spirits from depalletizing stations or replenishment zones through WMS-directed routes to fulfillment lanes. The layout would support both zone-based and batch picking strategies, with diverters, labelers, and barcode scanners integrated along the line for accurate routing and tracking.

Zero-pressure accumulation zones can be used to protect fragile products from impact, while elevation changes and spiral conveyors would connect case flow to mezzanine levels or sorting chutes for outbound staging, ensuring fast, controlled movement of individual cases throughout the order cycle.

Motorized pallet conveyors form the backbone of the facility’s heavy-load transport system, linking dock doors, staging areas, palletizers, mixed-layer pallet building terminals, wrappers, and storage lanes in a continuous loop.

Pallet conveyors are the typical entry choice for a beverage distributor looking to begin automating their facility, as the system can replace costly lift-truck operations while increasing constant movement, stability, and flexibility.

Designed with chain-driven or roller-driven modules depending on pallet weight and size, these conveyors can be engineered to support both uni-directional and bi-directional flow, enabling the smooth transfer of full or mixed-product pallets across the warehouse. Strategically placed transfer cars or turntables would allow for layout flexibility and efficient movement between perpendicular lines or multi-zone operations without requiring manual processes.

Pallet Handling Equipment

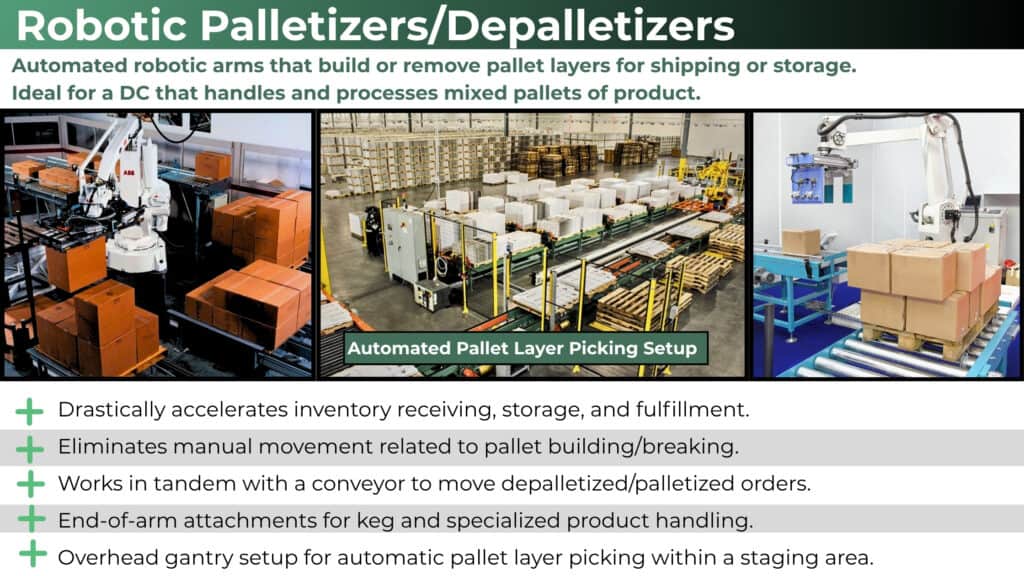

Robotic palletizers can be deployed near the end of the case conveyor picking lines to automatically build mixed or full-SKU pallets based on dynamic customer orders, using layer-forming tables and programmable patterns suited for cases of bottles or cans.

Depalletizers can be installed at the receiving side of the warehouse or near sortation zones, where they would unload inbound pallets and singulate cases directly onto conveyors for putaway or replenishment.

These robotic arms are usually outfitted with vacuum suction cups to handle a variety of case dimensions common in beverage distribution. End-of-arm tooling can expand it’s ability to handle single bottles (for packaging), kegs, or specialized non-conveyables (mini-kegs, bagged liquids, oversized promotional items, etc.)

For mixed-layer orders the ideal solution can be an automated layer picking system using flow rack, a central pallet conveyor line, and an overhead gantry palletizer. This setup automates highly-technical mixed SKU orders that are difficult to process manually without error.

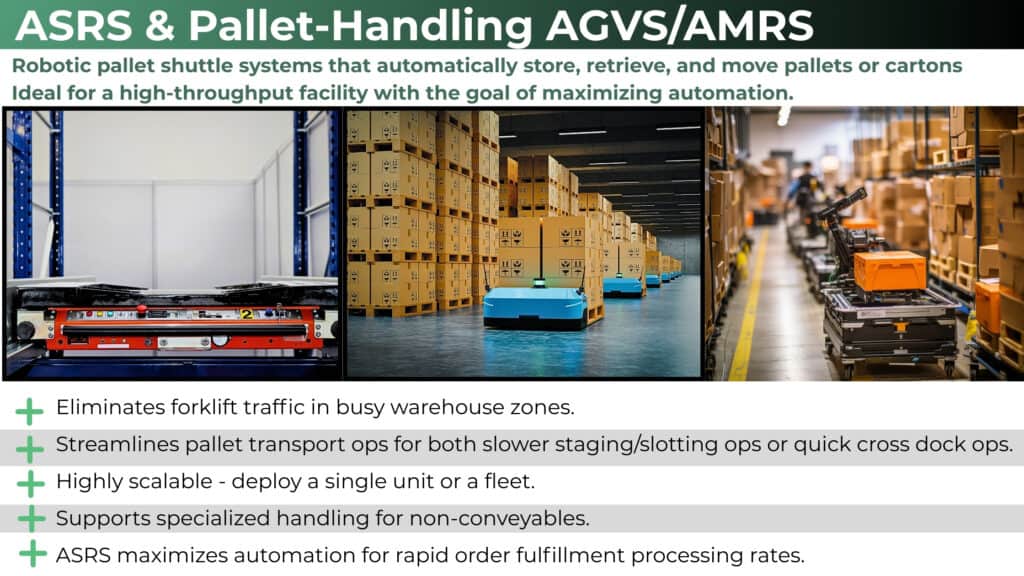

In a high-throughput wine, spirits, or beer distribution center, ASRS units would be engineered into the facility’s racking layout to enable automated vertical and horizontal storage of full pallet loads, typically segmented by product type, SKU velocity, or expiration date. An ASRS unit automatically retrieves and stores pallets, transporting the load on a large shuttle and inducting it to an outfeeding pallet conveyor source.

Integrated AGVs (automated guided vehicles) or AMRs (autonomous mobile robots) would be programmed to transport pallets between receiving, storage, picking, and outbound staging zones without requiring human-operated forklifts. These mobile units would follow predefined paths or dynamically update routes based on real-time WMS instructions, supporting both full pallet movement and partial pallet replenishment, and eliminating congestion in high-traffic dock or pick areas. This is ideal for slower moving operations

Ancillary Automation

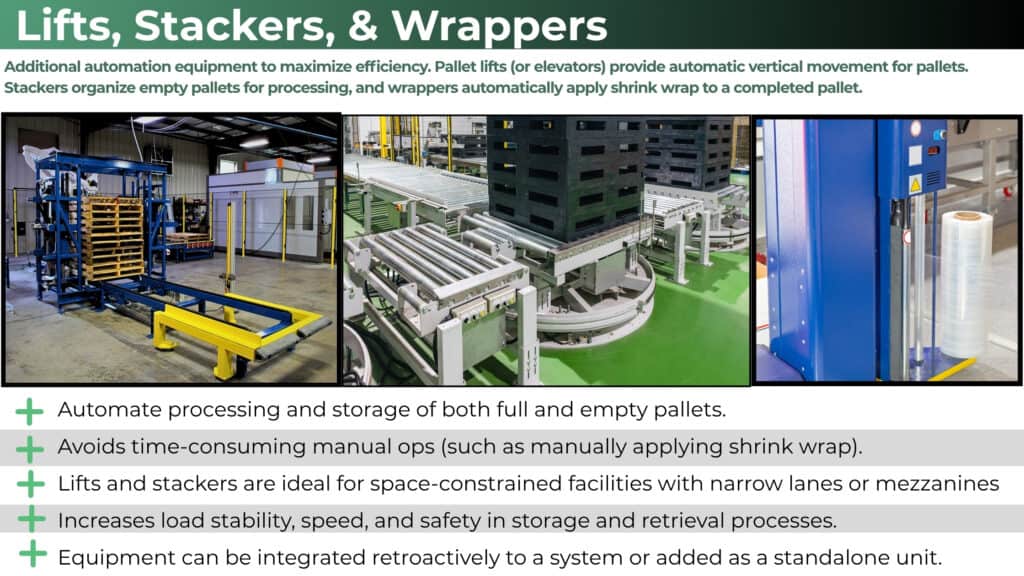

Pallet lifts would be installed to vertically move full or empty pallets between ground-level conveyors and upper-level storage or mezzanines, particularly in multi-tiered facilities where vertical space optimization is key. This eliminates the requirement for a forklift and removes the vertical retrieval limitations associated with running lift equipment. Pallets can be stacked much higher with upper-level equipment or structural racking and processing these orders can be achieved with lifts and proper conveyor routing.

Stackers would be located at inbound and outbound docks or near robotic palletizers to automatically handle empty pallets for reuse or staging, maintaining a consistent supply of pallets without manual stacking. Stackers can be integrated into a pallet conveyor line that can automatically induct itself when an empty pallet is called for processing.

Automatic stretch wrappers (or strappers in some situations) would be positioned near the end of the fulfillment line, integrated with pallet conveyors, to automatically rotate and wrap completed loads using stretch film. Certain wrapper units can be equipped with scales for outbound weight checks and WMS verification.

These systems can be deployed as stand-alone units or integrated within a line to maximize automation while decreasing reliance on manual labor.

See a Century wine and spirits distribution system in action

Contact Century

Wine, spirit and beer distributors have a fair share of operational challenges within their industry. Coupled with the current shift to specialized drinks with less demand for traditional beverage offerings, operators are looking for solutions to remove barriers and costs while pivoting their inventory to what’s selling.

Century Conveyor can design, build, and provide post-launch support for an automation system engineered precisely to your needs. Our extensive experience in the WS&B distribution industry guides us in engineering solutions that directly solve your top issues while providing efficiency, performance, and ROI.