Walk into almost any established warehouse or distribution center and ask a simple question:

“Do we have a fully accurate, up-to-date facility layout?”

Most of the time, the answer is complicated.

There’s a CAD file from years ago. A PDF that’s been marked up and re-marked up. A mezzanine that was added but never properly documented. Conveyor lines that were extended during peak season. Utilities that were rerouted to solve a short-term problem and never updated in the drawings.

Individually, these changes seem minor. Collectively, they introduce risk—risk that quietly compounds until the next major conveyor expansion, automation retrofit, or system integration project exposes the gap.

For warehouse managers, operations directors, and industrial engineers, warehouse layout management is no longer a clerical task. It is a strategic function that directly impacts cost, speed, scalability, and long-term ROI.

This is where a professionally implemented LaFayette Magnetic Sortation (LMS)—like the one offered by Lafayette Engineering—changes the conversation.

The Foundation of Every Conveyor and Automation Project

Every successful conveyor system planning effort starts with a basic truth: you must know exactly what exists before you design what comes next.

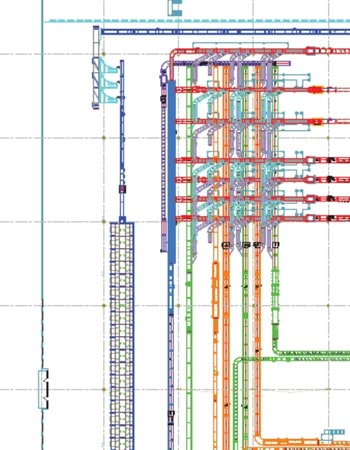

When Century Conveyor begins a new project—whether it involves sortation, pallet conveyor, robotics, or broader material handling system design—the first step is understanding the real-world constraints of the facility. That includes column grids, clear heights, structural load capacities, egress paths, utilities, and the precise location of existing equipment.

If that information is inaccurate, incomplete, or outdated, the design team is forced to compensate. Sometimes they design conservatively, building in extra clearance to avoid unknown conflicts. Other times, they discover issues only after installation begins—when field crews find that a beam is lower than expected or that an undocumented utility line runs directly through the planned conveyor route.

The result is almost always the same: rework, delay, cost escalation, and frustration.

The Project Management Institute consistently identifies poor documentation and scope misalignment as major contributors to project overruns.

Project Management Institute – https://www.pmi.org

In industrial environments, those overruns are not theoretical. They show up as expedited freight, field modifications, redesign hours, and extended downtime.

The irony is that many of these issues are preventable. The missing ingredient is facility layout accuracy.

The Quiet Cost of Outdated Drawings

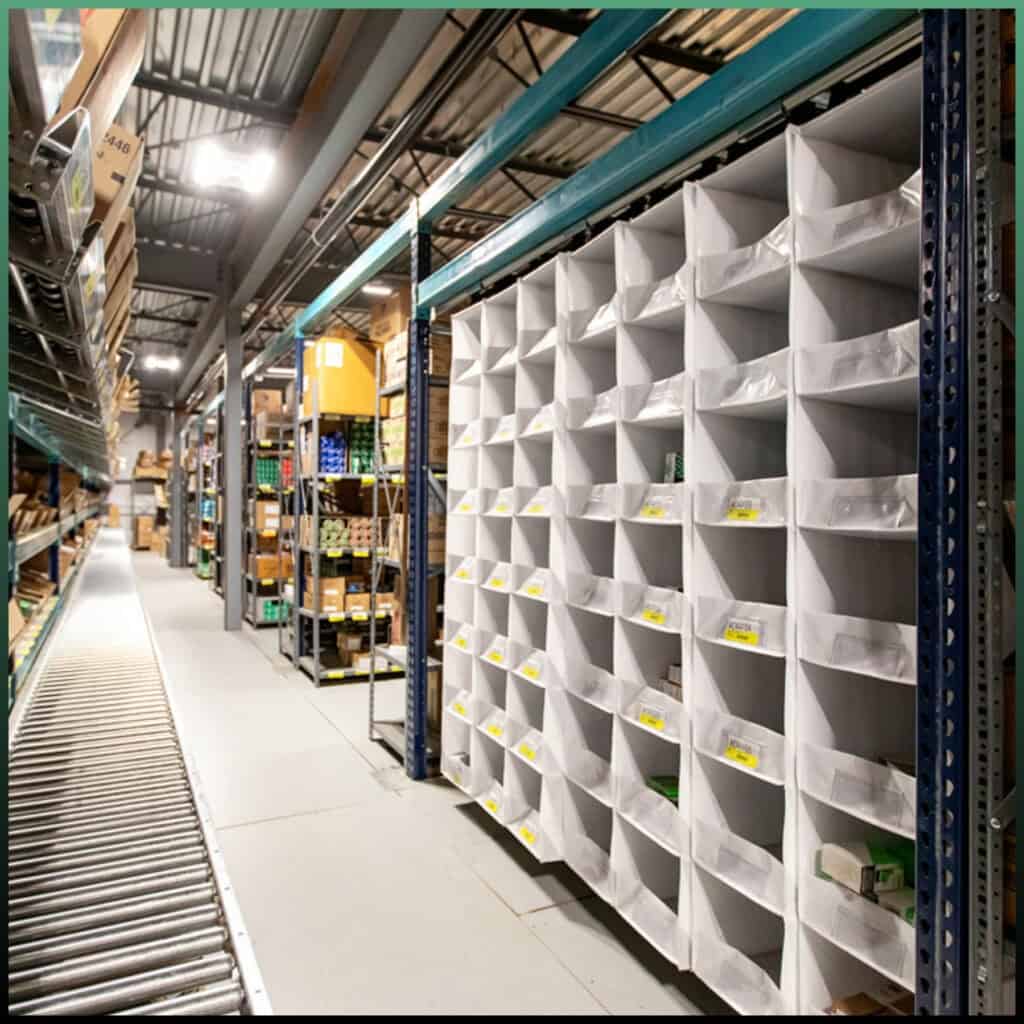

Warehouses are living systems. They evolve continuously.

A new pick module is installed to handle e-commerce growth. A temporary conveyor extension becomes permanent. Racking is relocated to increase density. A mezzanine is added to accommodate seasonal labor. A maintenance team reroutes compressed air or electrical lines to solve an operational bottleneck.

Each change makes sense at the time. But if documentation does not keep pace, the facility’s “official” layout gradually diverges from reality.

Over time, that divergence becomes more than an inconvenience. It becomes operational and financial exposure.

Consider safety compliance. OSHA regulations require safe working environments, including proper egress and equipment clearance.

OSHA Standards – https://www.osha.gov/laws-regs

If emergency exit paths or equipment clearances are inaccurately documented, audits become more complicated. Risk increases.

Now consider capital planning. When leadership evaluates automation upgrades—robotics, AS/RS systems, high-speed sortation—they rely on layout data to assess feasibility and ROI. If that data is unreliable, capital decisions are made on shaky ground.

According to McKinsey research, advanced warehouse automation can improve productivity by up to 30%.

McKinsey Supply Chain Insights – https://www.mckinsey.com/capabilities/operations/our-insights

But automation success depends on precise spatial understanding. You cannot accurately simulate throughput, density, or workflow without a trustworthy baseline.

Outdated drawings quietly undermine strategic growth.

From Static Drawings to Strategic Asset

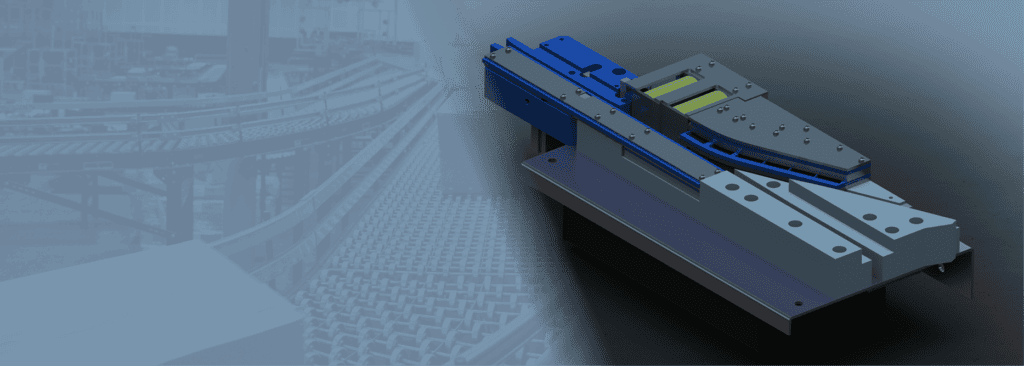

This is where the concept of a LaFayette Magnetic Sortation (LMS) becomes transformative.

An LMS is not simply a shared folder of CAD files. It is not a one-time drafting update. It is a structured, controlled approach to managing the physical intelligence of an industrial facility.

Think of it this way: just as operations teams use warehouse management systems (WMS) to control inventory and workflows, an LMS governs the physical environment itself.

A well-implemented LMS centralizes and standardizes:

- Facility layouts

- Conveyor routing

- Equipment positioning

- Racking configurations

- Structural elements

- Utilities and service pathways

Instead of static drawings that slowly degrade in relevance, the facility becomes a documented, version-controlled, continuously updated system.

For operations leaders, that shift is powerful. The facility is no longer a black box that engineers must rediscover every time a project begins. It becomes a known, measurable asset.

How Lafayette Engineering Approaches LMS

Lafayette Engineering developed its LMS offering specifically for industrial and material handling environments. Their background in material handling system design and automation engineering shapes how they approach layout management.

The process begins with clarity.

Rather than relying on assumptions or legacy drawings, Lafayette Engineering focuses on capturing the true current state of the facility. That may involve on-site verification, dimensional confirmation, and structured updates to ensure that structural elements, conveyor systems, elevations, and utilities reflect real-world conditions.

But the real value is not just in the initial capture. It is in how the information is organized and maintained.

Lafayette Engineering structures layout data in a way that supports long-term scalability. The documentation is standardized so it can be used effectively for:

- Future conveyor expansions

- Warehouse automation initiatives

- Maintenance planning

- Capacity modeling

- Structural feasibility analysis

Changes are tracked. Versions are controlled. Updates are integrated into the master documentation.

In short, the LMS transforms industrial facility documentation from an afterthought into a managed system.

To explore the full scope of the service, visit:

Lafayette Engineering LMS – https://www.lafayette-engineering.com/lms/

The Strategic Advantage for Warehouse Leaders

For warehouse managers and supply chain executives, the benefits of disciplined warehouse layout management extend far beyond cleaner drawings.

First, risk decreases. When Century Conveyor evaluates a new conveyor installation or system integration project, accurate layout data reduces the likelihood of field surprises. Projects move faster and with greater confidence.

[Internal Link: Conveyor Systems Page]

Second, planning accelerates. Instead of spending weeks reconciling outdated documents, engineering teams can begin analysis immediately. Budget estimates become more accurate. ROI calculations become more credible.

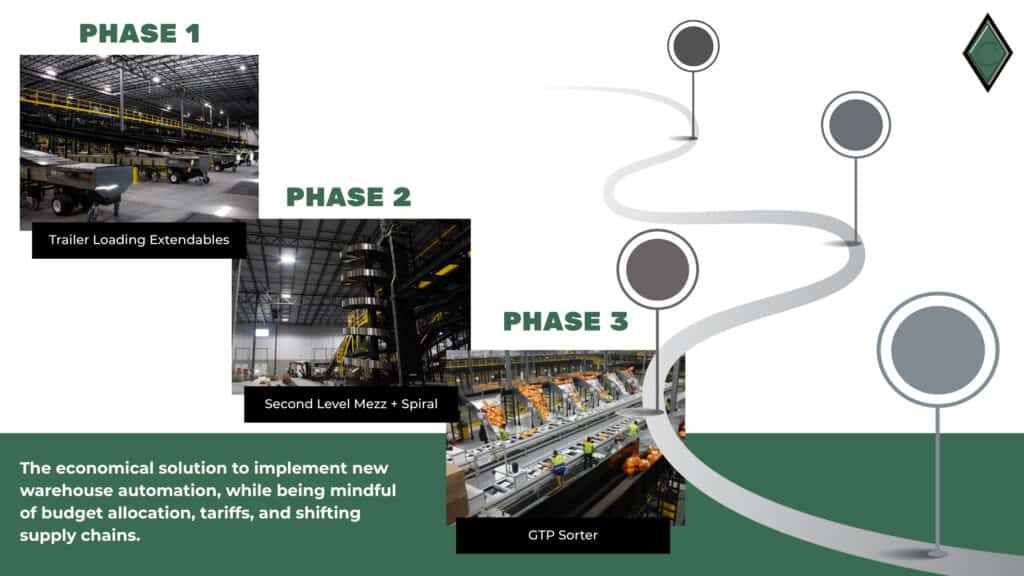

Third, long-term capital strategy improves. With reliable layout data, leadership can model phased automation rollouts rather than pursuing reactive, piecemeal upgrades. Mezzanine additions, pick module expansions, and sortation retrofits can be evaluated in the context of a documented roadmap.

Fourth, cross-functional alignment strengthens. Maintenance teams, engineering departments, and executive leadership reference the same controlled documentation. Discrepancies decrease. Decision-making becomes faster and more informed.

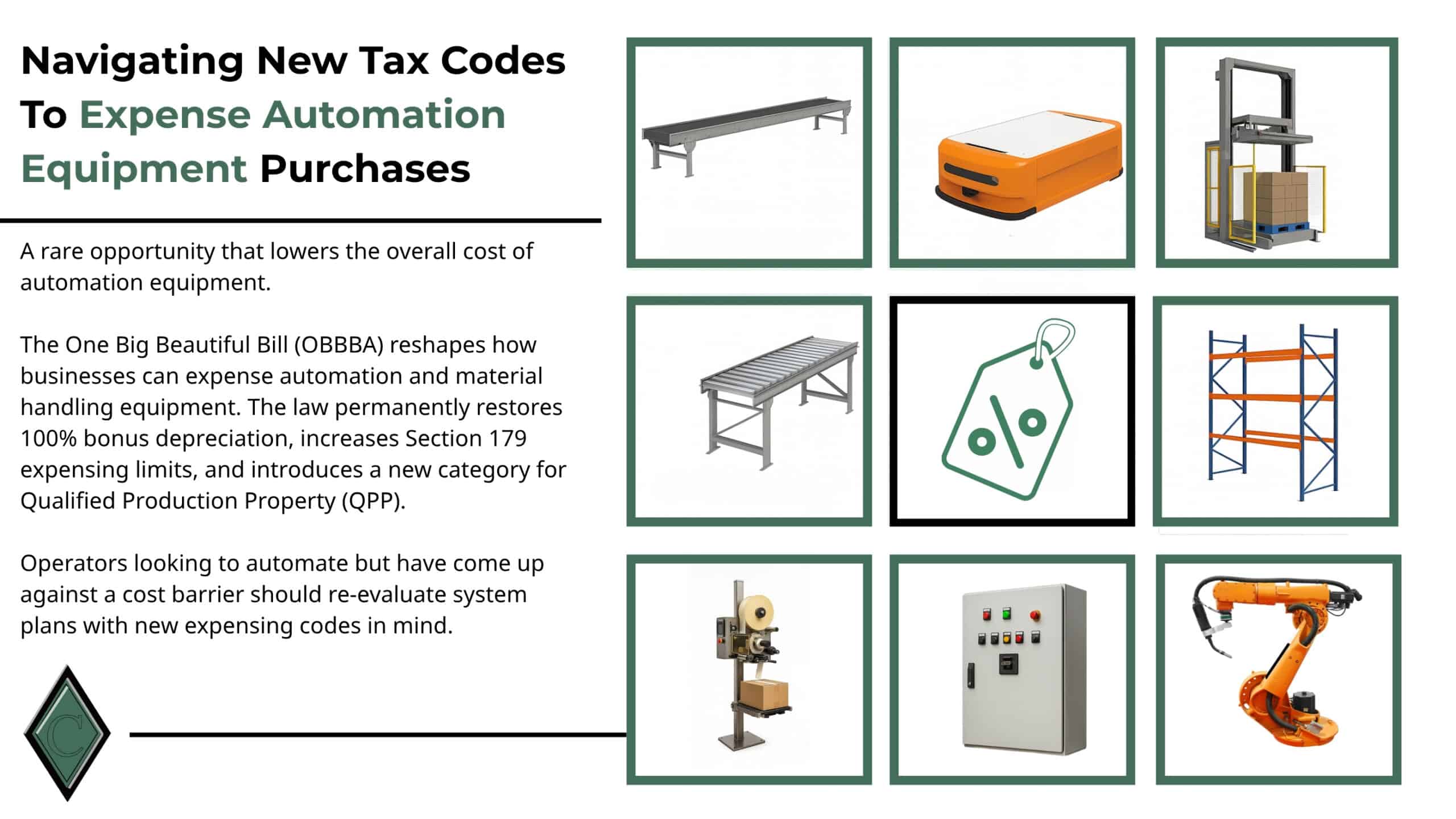

When viewed holistically, an LMS is not a drafting expense. It is a risk management tool and a strategic planning platform.

Why Layout Accuracy Is a Competitive Differentiator

The broader industry trend is clear. Organizations like the Council of Supply Chain Management Professionals (CSCMP) emphasize agility and infrastructure readiness as critical competitive factors.

CSCMP – https://cscmp.org

Agility depends on visibility. Visibility depends on accurate data.

Facilities that invest in layout precision are positioned to:

- Scale automation quickly

- Adapt to shifting demand

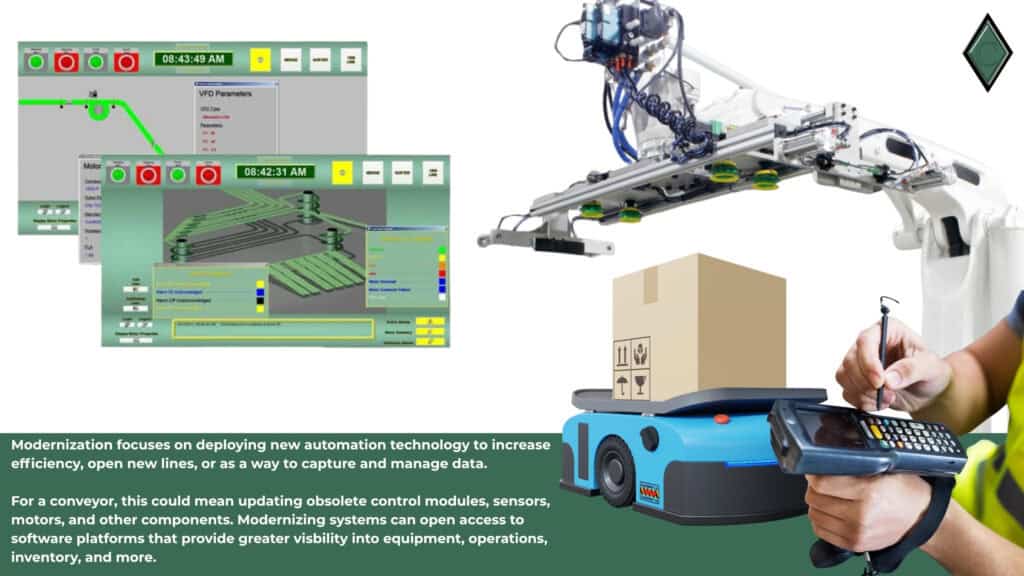

- Integrate robotics and new technologies

- Reduce downtime during upgrades

- Attract investment with confidence

Facilities operating from outdated documentation must rediscover their constraints each time change occurs.

Over time, that difference compounds.

A Stronger Partnership Between Century Conveyor and Lafayette Engineering

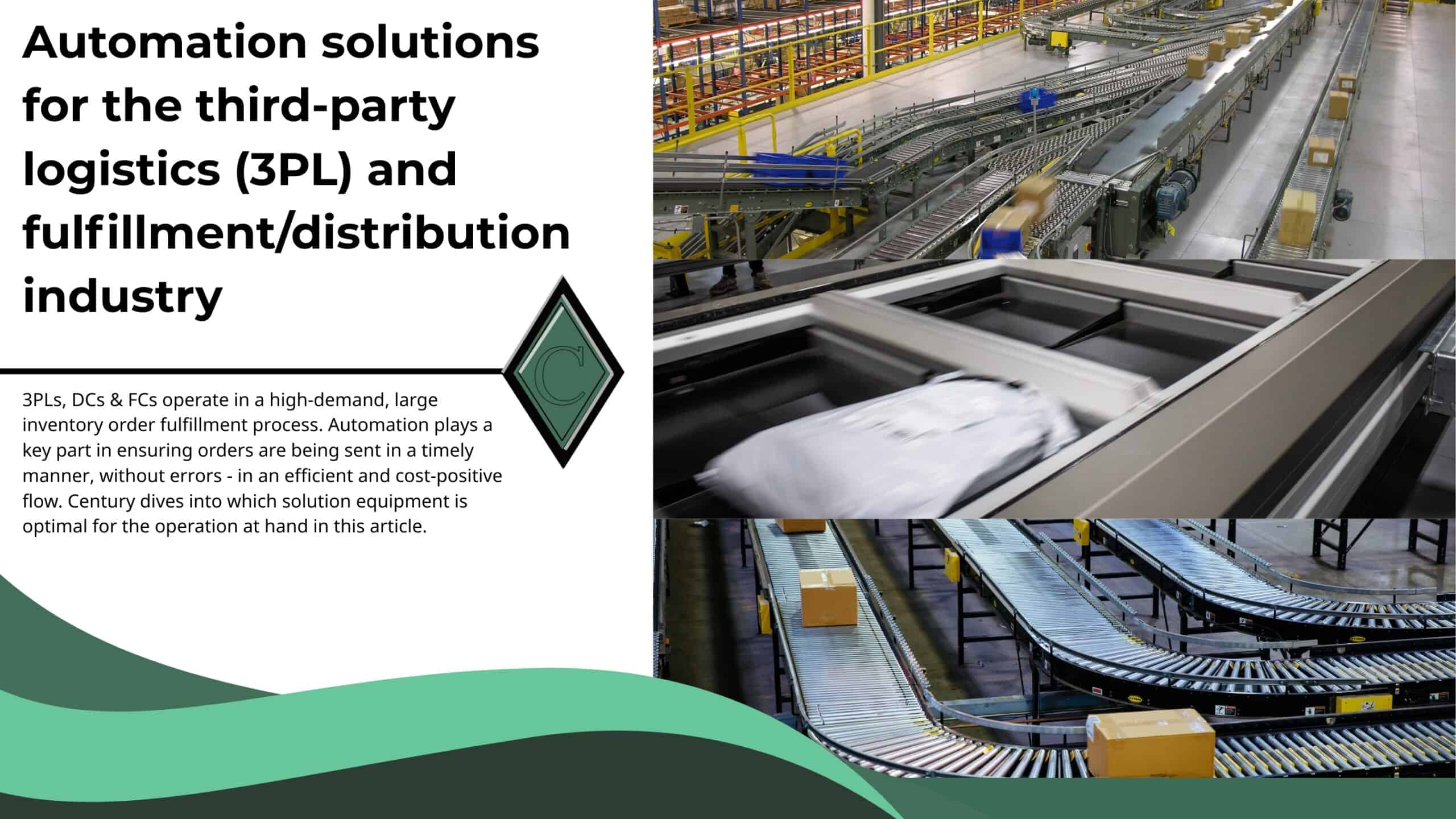

Century Conveyor is known for delivering engineered material handling solutions that solve real operational challenges. But even the most advanced conveyor system design depends on accurate foundational data.

By leveraging Lafayette Engineering’s LMS capabilities, Century Conveyor clients gain a strategic advantage before the first piece of equipment is installed.

Designs are grounded in reality. Risks are identified early. Installation proceeds with greater certainty. Future expansion paths are clearer.

The result is not just a successful project—it is a stronger, more resilient facility.

From Reactive Documentation to Proactive Strategy

Industrial operations are under constant pressure to move faster, handle more SKUs, manage labor volatility, and justify capital investments.

In that environment, facility layout accuracy cannot remain an afterthought.

A disciplined LaFayette Magnetic Sortation (LMS) transforms documentation from a reactive exercise into a proactive strategy. It supports smarter conveyor system planning, more effective warehouse automation, and stronger long-term operational performance.

If your facility drawings are outdated, fragmented, or inconsistent, now is the time to address it—before your next automation initiative exposes the gap.

Explore Lafayette Engineering’s LaFayette Magnetic Sortation to see how engineered layout precision can reduce risk and strengthen your facility’s future:

👉 Learn more about Lafayette Engineering’s LMS:

https://www.lafayette-engineering.com/lms/

Or connect with Century Conveyor to discuss how accurate layout management can improve your next material handling initiative:

In modern distribution environments, precision is not optional.

It is competitive advantage.