Automatic Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) have existed for years now, offering robotic material handling operations for a multitude of warehouse operations. The industry is well aware of its pros and cons, and supply chain executives are content with placing them within their arsenal of automated warehouse solutions.

The much harder decision when automating is understanding which solution will provide the most benefit, as opposed to if it will at all. In the case of AGVs and AMRs, conveyor systems are tried and true forms of automation that continue to provide exceptional output and return-on-investment. While both solutions differ in engineering and functionality, both exist for the same goal- reliable, stable, and quick movement of items. How do AGVs/AMRs stack up against traditional conveyor systems? Where does one solution shine, while another does better in a different application?

Century has experience integrating both and understands where and how these systems outperform one over the other. We wanted to share some of our insights so you can evaluate what works best for your warehouse.

AGV and AMR

AGVs and AMRs are often grouped together, mostly because the operations they perform overlap with each other. The single main difference between the two is its form of sensing and moving throughout the environment. AGVs move by using a sensor that follows a set path (typically a form of sticker or tape on the ground-hence the word “guided” in its name). AMRs move by sensing objects around them, and learning an optimal path (hence the word “autonomous” in its name).

This characteristic defines what operations are typically assigned to an AGV or an AMR. Essentially, AGVs work best at moving cartons and pallets across the facility with little to no variation in its traveling path. AMRs shine in picking operations, where it would not have a set path.

AGV

Effective in moving, tugging, and towing cartons or pallets from a single location to another.

- Carts

- Tuggers

- Lift-Truck

- Pallet Jack

- Unit Load

AMR

Assistance in multi-variable operations that require diversion in movement paths.

- Picking

- Sortation

- Inventory Control

- Sanitization

AGVs and AMRs have seen expanded use over the course of the past year, and most new warehouses are built with the notion that automation will be implemented at some point. According to Research and Markets, United States, Germany, U.K., China and Japan are going to lead the market with an annual demand of more than 200,000 mobile robots (AGV & AMR) by 2026.

To put the cost-effectiveness of an AGV and AMR into perspective, Annual costs for a forklift operator can run up to $50,000. If a forklift has to be operated around the clock, then at least 3-4 drivers are needed. Adding the invest costs of $10,000 for a forklift truck to the personnel costs, the annual costs for one forklift come to over $200,000 (ResearchAndMarkets.com). Depending on the output of the warehouse, operating AGVs and AMRs can save thousands over traditional manually operated lift trucks.

Automated robotic solutions continue to improve as newer technologies are created and adapted. Artificial intelligence (AI), machine vision, voice-to-robotic-pick, and warehouse data-driven learned actions continue to provide added functionality and benefit to AGVs and AMRs (primarily the latter). This makes AGVs and AMRs a forward-facing implementation, as abilities are added to their repertoire of functionality through the advancement of warehouse technologies and software capabilities.

Conveyor

Conveyor systems are the typical solution of any automated operation, offering a continuously moving assembly line to quickly complete the processing and distribution of a package. Conveyors use belts or rollers to move cartons or pallets, powered by motors. Each warehouse that employs conveyors has a specially engineered layout, consisting of a variety of conveyor sections, depending on function.

Conveyor Section Types

- Infeeding

- Straight

- Curved

- Incline

- Decline

- Divert

- Merge

- Switch

- Outfeeding

Conveyors produce the best results when implemented in fast-moving post-production operations such as order fulfillment, product distribution, sortation, and crossdocking. Conveyors are highly customizable, with the number of systems that can be added to the conveyor line spanning from carton forming to in-trailer loading, and everything in-between. Conveyors have proved the test of time as being the main system of reliable and quick movement in a warehouse. There’s a reason they’re still in use for over 100 years. The output rate is unmatched and its simplicity in design help it to easily integrate with other cutting-edge automation solutions.

The Most Important Factor: Your Warehouse

If you were to ask us what system we would use, we would ask “what’s your warehouse like?”. This is the number one question you should ask yourself as you’re exploring solutions. The effectiveness and benefit of these solutions are only relevant if integrated correctly in your distribution center, warehouse or facility.

To simply it even further- think on your answer to this question. Can your operations continue effectively if you install a “bolted-down” conveyor system. If the answer is a definite “NO”, then you’ll most likely benefit more from the use of AGVs and AMRs. A fully engineered conveyor system is not mobile, and if your warehouse has limited space, or needs open lanes for lift trucks to travel in, a conveyor system may not be ideal. That’s not to say it’s impossible to engineer, but an AGV or AMR would be a more realistic solution.

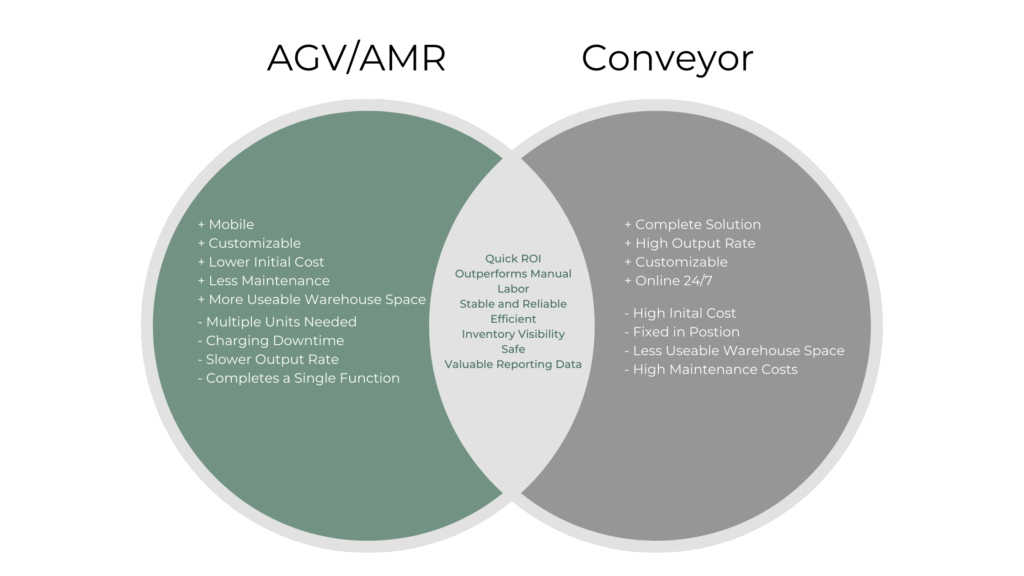

With that in mind, here’s our comparison between AGVs/AMRs and conveyor systems.

The Comparison

Key Takeaway

Both systems will complete the task of transporting product across a warehouse, it’s that your operations and facility space will determine which one will work better.

AGVs/AMRs are ideal for warehouses that have:

- Limited space and cannot install a conveyor system.

- Extensive pick operations

- Forklifts transporting the majority of items

- A healthy output rate (5,000 to 20,000 cartons shipped per day)

Conveyor systems are ideal for warehouses that have:

- Flexible space arrangements

- A variety of package types

- Extensive sortation operations

- A high-output rate (20,000+ cartons shipped per day)

Both AGVs/AMRs and conveyors can benefit in more ways than one, and in many cases, are both implemented in a facility to maximize distribution operations.