Operating a wholesale distribution process is a complex series of moving parts. Each organization has a mix of inventory and typically involves itself in the process of purchasing, storing, and selling products to end buyers like retailers or other wholesalers. With the number of items wholesalers handle daily, it’s no surprise that many invest in automated solutions to enhance operations.

“Product availability and quality is a key element, together with a delivery service that is accurate and efficient is a driving force for businesses.”

Sedat Kaan Hendekli

Head of Operations at JJ Foodservice

Source: BetterWholesaling.com

The burning question is, what automation works best for the wholesale industry? We’ve compiled a list of 10 automation applications that we’ve experienced integrating in the past for some of our wholesale clients.

1. Robust inventory management system

The ability to have complete visibility of a wholesale operation at all times is paramount to effective distribution. A warehouse management system (or WMS) stores vital information such as scan dates, storage location, supply quantities, and a multitude of SKU data for ordering. Depending on the manufacturer, automation systems can integrate with a WMS and provide even more functionality and reporting data.

Besides being a source of important product information, a WMS can apply that information within your warehouse operations. For example, if the wrong item is picked and placed on an outbound conveyor, the scan tower will read the label and the WMS will recognize it is in the wrong batch, stopping that section of the conveyor and sounding an alarm for a worker to remove the incorrect item.

2. Robotic palletizing for redistribution

For wholesalers who use pallets, either robotic palletizing solutions automatically build and break a pallet. A wide variety of robots and end of arm tooling can accommodate most carton sizes and complex layer build configurations for pallets.

The speed and stability of robotic palletizing greatly outpace that of manual pallet building and even lift trucks. For further automation, completed pallets can be conveyed from a robotic cell to an inline stretch wrap operation, replacing tedious manual wrapping.

3. Rapid order fulfillment

Delivery expectations have greatly increased in recent years, primarily due to the prevalence of same or one-day shipping offerings online. Those expectations have extended to wholesaler clients, whose operations must match a competitive wholesale e-commerce landscape. Much like adjacent markets (third-party logistics, for example), automating order fulfillment is key to satisfying customers, while also offering an edge over the competition who don’t have quick shipping incentives.

A tried-and-true conveyor system is best suited for order fulfillment. Depending on the size of the warehouse it’s installed in, and the product being transported, a conveyor system can include a variety of automation:

- Pack Tables

- Carton Forming

- Carton Sealing

- Label Printing and Application

- Destination Sortation

- Loading Assistance

4. Automation-aided picking

For most wholesale operations, an inventory boasting thousands of different products and items is normal. Order picking is usually where inefficiencies are identified, as manual labor is greatly outpaced by a variety of automation solutions.

- ASRS

- An ASRS (Automatic Storage and Retrieval System) uses a crane attached to a horizontal and vertical track, scaling the racking structure, and using extendable forks to handle pallets. The operator terminal provides information on what product is stored where, and the ASRS operates when a retrieve or store command is inputted.

- AMR/AGV

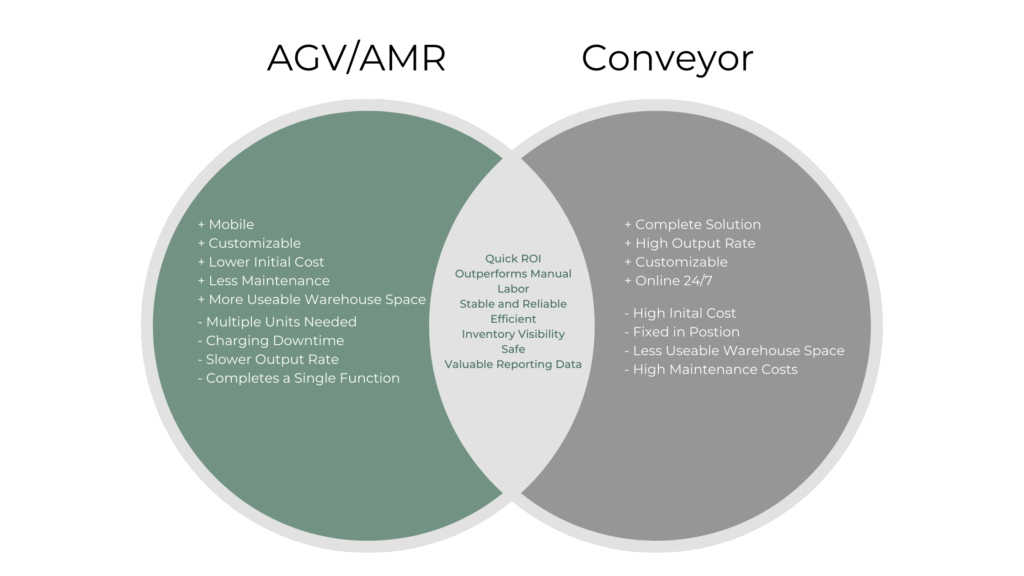

- Automated Guided Vehicles (AGV) and Autonomous Mobile Vehicles (AMR) both provide a multitude of functions, typically moving items from one area of the facility to another, absent of human interaction. The difference between the two is in the way it senses the environment. AGV’s move by using a sensor that follows a set path (typically a form of sticker or tape on the ground). AMRs move by sensing objects around them, and learning an optimal path. In this sense, both have applications that one or the other is better suited to.

- Shuttle Systems

- For the best of both worlds, a shuttle system utilizes pick robots within a racking structure. When an order is being fulfilled, the robot navigates to the compartment where the item is held, retrieves it, and brings it to the worker’s pack station or an item dispenser receptacle.

5. Flexible packaging

It goes without saying that a massive catalog of products varying in weight and size would need packaging solutions just as versatile.

Automation systems, such as conveyors, are manufactured in different dimensions and applications and can be engineered in a warehouse layout to accommodate cartons of varying sizes and fragility.

We go in-depth on carton packing solutions in our 3PL Automated Box Packing Solutions for Powerful and Profitable Order Fulfillment post.

6. Reliable sortation

Sortation systems separate products for induction into individual lanes typically associated with an outbound destination. Various types of sortation and conveyor systems are often connected to comprise a fully functioning material handling solution.

Wholesalers supply a diverse range of customers from all over, so quick, and accurate diverts are required to keep items moving and heading to the right destination. Selecting the correct type of sortation system is where the most thought should be put, as it all matters on the dimensions of the product being moved.

7. Effective pallet handling

Pallets can be cumbersome to transport throughout a warehouse, so offering simple solutions to warehouse workers to decrease human touchpoints with pallets can prove effective.

- Pallet conveyor

- Pallet flow rails

- Pallet lifters

- Pallet positioners

- Gravity racking

- Tugger and dolly attachments for AGVs

8. Maximize warehouse space

Wholesale warehouse space is extremely precious. Ensuring there’s room for storage, order fulfillment, loading, maintenance, employees, and office- all while following building codes, is no easy feat. If space is at a premium, but additional systems will need to be implemented in the future, a few capacity-saving solutions can provide some leeway.

- Inclined and spiral conveyors

- Suspended conveyor sections above the warehouse floor.

- Mezzanine structures

- Walkways and platforms suspended above the warehouse floor.

- Narrow-aisle racking

- Special forklifts can be used to access pallets in these lanes

- ASRS

- Automated cranes travel within narrow-aisle racking structures to retrieve pallets

- Shuttle system

- Items are held in compartments within a complete racking structure, eliminating aisles completely.

9. Accurate reverse logistics

Returns are a constant area of disconnect in operations when it comes to order fulfillment. There needs to be a planned intake process to return the items to storage and re-fulfill the order with the correct products.

When returns enter back into a warehouse, they’re put in a separate staging area. Depending on the condition of the item, or whatever the nature of the return is, it may be returned to inventory, sent to another distributor who sells discount items or discarded.

Once a return item has been rescanned in the system, the customer’s order will either be marked as fulfilled (so they can receive their money back) or another order will be placed (in the event they were sent the wrong item, but they still need the correct item sent to them).

10. Forecast planning and optimization

Warehouse automation continues to improve as newer technologies are created and adapted. Artificial intelligence (AI), drones, machine vision, voice-to-robotic-pick, and warehouse data-driven learned actions are just a few examples of what’s on the horizon.

The wholesale industry is only going to grow, and understanding the current constraints of your warehouse, and the projected sales volume per quarter should be your guiding logic as to what automation can be implemented, and when.

Century Systems has had experience engineering systems for the wholesale industry (here’s a case study on a past client of ours), and we understand the importance of reliable and stable output rates. All of our projects are designed to be as efficient, turnkey, and results-driven as possible.