Venturing into the world of distribution center and warehouse automation poses many questions, a burning one being “Where do I start?”

It’s critical to select a solution that checks off all your operational improvement boxes but doesn’t run up against parameters that you need to maintain. For automation to perform as best as it can, careful preparation and engineering must be done, among a few other tasks.

- Identify inefficiencies

- Evaluate existing systems

- Consider demand futures

- Warehouse capabilities

- ROI analysis

- Internal coordination

- Assemble a project team

Century wants your warehouse automation operation to perform as well as possible, no matter what it is. Our recommendation is to complete a few or all the steps below before you begin.

Identify inefficiencies

Is there an obvious weak point in your warehouse that automation could solve? Or has it been a while since you’ve looked at efficiency reports or commenced in continuous improvement? It’s important to understand the current challenges your warehouse faces and validate that the automation solution you’re researching will solve most of those issues.

Another component to this point is predicting the operational outcome of the integration. Will your other manual operations be able to seamlessly accommodate for the increased processing rate? Evaluate potential impacts the system may have on other areas of your warehouse and adjust accordingly.

Evaluate existing systems

Updating older equipment that’s already a part of your operations is the simplest way to increase output and bolster distribution. The typical lifespan of most systems varies, but it may be time for an improvement solution if it’s over 15 years old.

Even if the solution still operates well, the advancement of material handling technology has increased drastically, and a newer, more modern application can outperformance the current system and provide additional functionality.

Consider demand futures

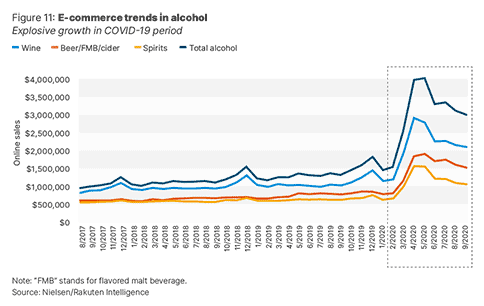

What are the predictions for the future of the industry (or industries) you primarily supply distribution services for? Is there an expectation for growth? If so, can your current operations realistically sustain satisfactory output? Consider the direction your company is heading in and apply automation in a way that’s flexible.

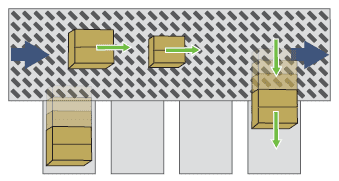

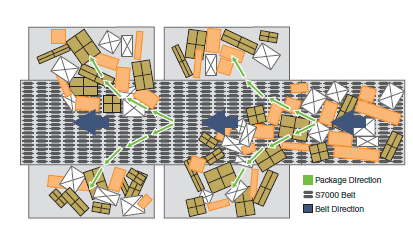

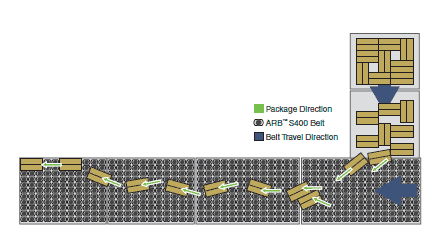

For example, there might be an exception in the future to handle products that have unique dimensions. Is the automation solution you’re researching able to transport smaller or larger products? Maintaining a dynamic, forward-thinking mindset and applying it to warehouse automation applications will benefit future expansion.

Warehouse capabilities

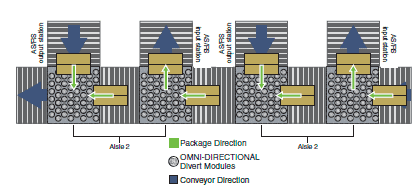

Every warehouse is different and has varying limitations and specifics. It’s important to understand this critical point, as some solutions may not offer optimal benefits if it won’t integrate seamlessly in your warehouse layout.

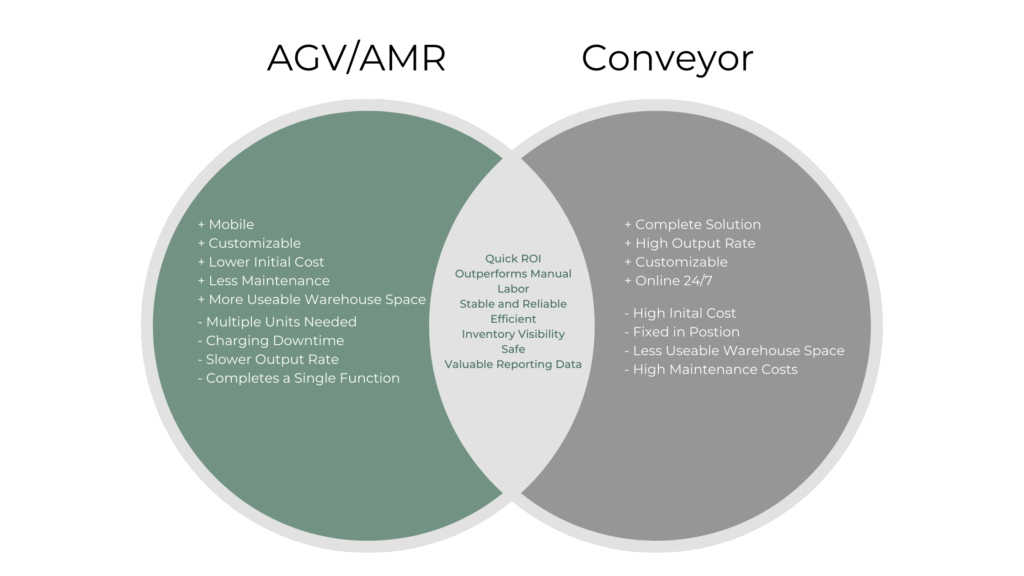

Keep in mind, many warehouse automation systems are designed with this mind. Mezzanines can be used to suspend conveyor lines in the air, while ground operations can continue unhindered below. Narrow aisle racking and autonomous lift trucks can be implemented to decrease the footprint of a storage structure. Robotic solutions like AGVs and AMRs come in multiple shapes and sizes and can move freely throughout a building without having to be “bolted down” in a static position.

When working with your engineers or an integrator, carefully examine the warehouse layout (typically a CAD drawing) and familiarize yourself with both limitations, and room for expansion.

ROI analysis

Price varies greatly depending on the automation solution used. Understand that it will pay itself back in time but know that the return-on-investment timeframe will be longer the more costly a system is. Take into account the system rates of the solution, what your current daily output is, and calculate the profits from the increase. Ensure that your ROI is financially viable and within your criteria.

Internal coordination

While you may be the main operations or warehouse executive, a good leader understands that they can’t possibly be aware of every oversight in their organization. It’s important to connect with other key individuals to gain a perspective on the warehouse challenges they encounter. Some of these departments may include:

- Staffing

- Maintenance

- Transportation

- Material suppliers

- Third-party supply chain partners

- Procurement

Scheduling a meeting to inform them of your automation initiative may bring about some pain points that the solution could solve or identify additional parameters that can be kept in mind as a solution is created.

For example, a maintenance lead may suggest a system that can be serviced easily or might have some insights about the warehouse that should be considered as an automation project commences.

Assemble a project team

Spearhead an effort to acquire resources to begin development. Depending on who’s employed at your organization, your team would ideally include engineers and project managers.

Alternatively, you can contact an automation integrator who will manage all aspects of the project. Here at Century Systems, we offer full-service automation engineering capabilities. Our team of engineers, project managers, account executives, fabricators, and installers see to it that your project is completed, from cradle to grave. Send us a message or give us a call to have a quick consultation with an automation expert.